News

Do you really need to be ready for Industry 4.0 or not?

Ready or not - we have come up with a solution that works for everyone.

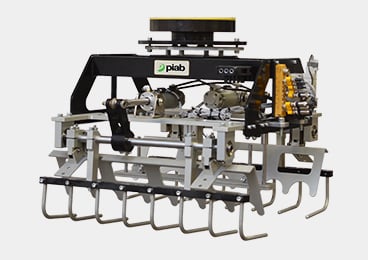

Heavy-duty bag gripper for palletizing

Piab introduces the first-generation end-of-arm tools in 25 and 50kg payloads for palletizing a wide variety of products.

Piab adds new sizes to bellows suction cup line

Extra sizes, more functions in additional fittings, and the entire bellows suction cup line included in the online configurator.

Piab is stepping up automation in the food industry, introducing a new vacuum-driven soft gripper

Cost effective solution for handling sensitive and difficult objects.

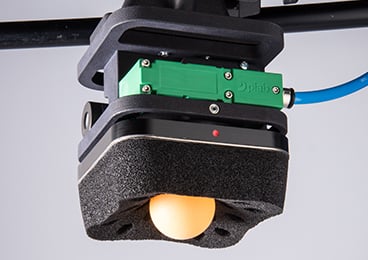

It’s SMART to be safe with Piab’s next-gen

Piab’s piCOMPACT®23 SMART vacuum ejector includes optocouplers to ensure extra safe operation.

Piab awarded recognition as one of Sweden’s Best Managed Companies

Piab has received the 2019 Sweden’s Best Managed Companies recognition, sponsored by Deloitte in cooperation with Nasdaq.

Another product family for the automotive industry

Piab maximizes productivity in the automotive industry with flexible suction cup mount.

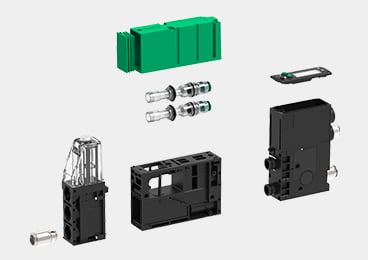

One plus one makes three!

Two years after acquiring Kenos®, Piab develops the perfect small business all-rounder – Kenos® KCS.

Yet another contribution to Industry 4.0

It is fascinating when you realize that you have developed the right product and the right functionality for the market and customer, even before all of the interest around Industry 4.0 came to light.

Piab’s Kenos® foam gripper head provides sweet success

The palletizing efficiency is doubled since the single Kenos® gripper picks multiple boxes of different sizes and weights.

Future proof conveying system for handling different types of tablets in a gentle but efficient way

We observed during the tests that piFLOW®t with piGENTLE® gave outstanding results.

Friction cups increase production by 33%

The Piab DCF friction cups released the parts much faster as compared to the competitive cups allowing to increase the press speed going from 10 SPM to 13 SPM.

Reduced assembly costs thanks to a piCOMPACT® all-in-one ejector

By changing over to our piCOMPACT® vacuum ejector, the customer reduced the installation effort thus saving time.

Split conveyor system proves ideal for contamination issue

With Piab's vacuum conveyor piFLOW®f the exposure to allergenic product is minimal and the cleaning process is decreased significantly.

Piab friction cups stamp out almost 700,000 more parts

The Piab friction cups provide a strong grip on oily surfaces and can withstand high shear forces resulting in parts no longer dropped and savings in damaged parts.

Dust-free filling thanks to the piFLOW®t vacuum conveyor with pre-separator

The customer opted for the Piab solution because we were able to achieve almost dust-free filling of the drying agent.

Strong reduction of chipping tablets by using our piFLOW®t tablet conveyor with pre-separator

The tablets can now be transported more product-friendly, resulting in a considerable reduction of scrap products.

SAR – A robot integrator saves 50% of air costs

The customer could use the robot to its full potential and still save 50% on air. Also, the installation time was extremely fast.

Sugar sieving output increased by 30% in the Confectionary/Candy segment

The process is now automated and due to less downtime for cleaning, the customer achieves a capacity increase of 30%.

Piab vacuum conveyor solves contamination issue

The split design of the Piab vacuum conveyor fulfilled the customer’s need of isolating the filter from the product receiver.

Safety first for chemical company using Piab vacuum conveyors

Piab’s dust-tight design reduced product loss to atmosphere providing for a cleaner, safer work environment and less product waste.