Success stories

At Nipro the piCOMPACT® provides the vacuum performance needed in production of pharma packaging made of glass

With 32,500 cycles per day, 24 hours a day, seven days a week, this application is one of those with the highest number of...

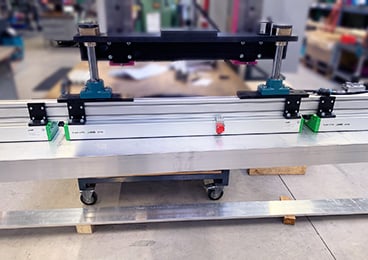

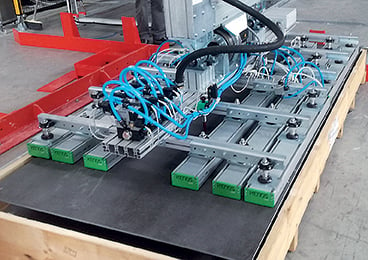

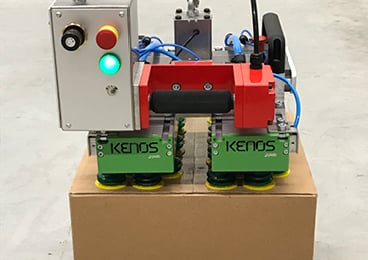

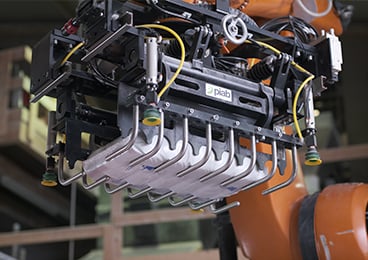

JAM Automation moves 250kg heavy profiles with Piab’s Kenos® grippers

To automaticaly remove extruded aluminium profiles from cassettes in high-bay warehouses, JAM Automation created...

Automatic handling of porcelain stoneware slabs and related sub-formats

Thanks to Piab's Kenos® KVG area vacuum gripper, an extreme variability of sizes and surfaces can be managed, using just a single gripper. This allowed...

High flexibility and safe gripping in a cosmetic application with Piab's cobot gripper

Effedi Automation chose the piCOBOT® gripper, COAX® vacuum technology and BX suction cups by Piab to handle the palletizing operations of a...

Industrial Bakery Austerschmidt in Germany automates handling of seeds with Piab’s vacuum conveyors

Employee relief and careful use of resources prompted the industrial bakery Austerschmidt in Germany to switch the handling of seeds from a manual to an automated process. In piFLOW®f vacuum conveyors, they found the critical tools.

With Piab's gripper, Best Handling Technology improves the ergonomics of its customer at 32 workstations

Healthy, satisfied employees, increased efficiency, flexibility, and sustainability - regardless of the industry, the reasons are always the same that give cause to a higher degree of automation in handling tasks. German Best Handling Technology was able to achieve all of this for its customer, a leading logistics service provider, with a suction cup equipped Kenos® area gripper.

DCL realizes flexible automation solution with Piab’s piCOBOT® vacuum gripper on an UR 10e robot

Looking for a flexible, easy to integrate, plug-and-play solution to handle picking and packing of items into boxes in their fulfilment center DCL Logistics based in Fremont, CA, resorted to an UR 10e robot combined with Piab’s piCOBOT® vacuum gripper.

Automatic handling of boxes and interlayers for the production of security cards

With a single gripper consisting of four B75 silicon suction cups by Piab, Robotecnik designed and manufactured a palletising robot to handle efficiently the end-of-line operations of Banca d'Italia.

Absolute precision in the handling of thermoforms, with sealing rings, and their transport supports

System integrator Umbra Control chose Piab's Kenos® KCS gripper, in a special version with four suction cups, to accurately and efficiently handle Meccanotecnica Umbra's end-of-line pick and place operations for the production of seals for the automotive industry.

Safe conveying of instant milk granules with Piab’s piFLOW®p vacuum conveyor

Polmlek Raciaz, a Polish producer of various milk-based products faced a problem of breaking granules during the transfer of instant milk within its process. In Piab’s piFLOW®p vacuum conveyor they found the solution they were searching for. Equipped with an ejector with a high vacuum flow, they were able to adjust the speed to maintain the granules as planned.

Automated palletizing of sweet tea and juice from a cold room

While palletizing cartons is a regular automation application, doing so from a cold room that is regularly hosed with water to stay clean is a specific challenge. Motion Controls Robotics overcame these by using vacuum technology from Piab supplied by Neff Group Distributors.

Handling cheese blocks right with Piab’s vacuum technology

Packaging cheese blocks vacuum-wrapped in film represents a major challenge for process automation. With the help of Piab’s piGRIP® configurable suction cups and high-performance vacuum ejectors, the machine and plant manufacturer TGW Robotics GmbH has developed a gripper that ensures a stable process.

Tradichem uses Piab’s vacuum conveyor to miniaturize active pharma ingredients

Size matters – particularly in competitive markets such as pharma and nutraceuticals due to its direct result on costs. Tradichems patented Hipering® process begins right at the start of the process chain by miniaturizing the ingredients. Thanks to Piab’s piFLOW®p vacuum conveyor their patented process is continuously fed thus maintaining the required pressure level.

Kora uses Piabs piFLOW®p vacuum conveyor for the efficient filling of superfoods

Fast and easy product changes, compliance with food and pharmaceutical standards, and high energy efficiency for sustainable resource conservation. For Kora the Piab vacuum conveyors are the perfect link between the process steps. Because they meet just these criteria.

Piab conveys micro-additives for pet and farm animal food in Conberg solution

While micro-additives are an important part in today’s pet and farm animal food, their strongly varying amount per recipe poses a challenge in automating the transfer from dosage stations to the mixer. System integrator Conberg in Poland developed a suitable solution based on Piab’s piFLOW®f vacuum conveyor.

robominds calls Piab's new MX suction cup the "Super Cup"

According to robominds, the latest vacuum technology product from Piab has earned this nickname because it simply lifts anything - regardless of the material, geometry, or surface structure. And so, the all-rounder is exactly the suction cup that robominds has been missing for its picking solutions for eCommerce customers and manufacturers of complex products.

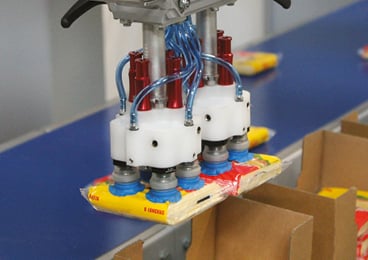

Automatic handling of cheese slice pouches of different formats at high process speeds

With the use of piGRIP® suction cups, certified for food contact, and COAX® vacuum generators, both Piab's products, CAMA Group has created a cutting-edge packaging system that allows to handle 280 pouches of cheese slices per minute.

Automatic handling of pasta packs

With the use of a single Kenos® KVGL vacuum gripper by Piab, Selematic has created a state-of-the-art automatic packaging system, achieving a significant cost reduction and an important productivity increase when handling different formats and various layers of pasta.

Automated veneer handling - sheet by sheet

With the help of Piab’s Kenos KVG area gripper, Heinrich Kuper GmbH carries out veneer sorting systems. The biggest challenge was to pick up split and perforated sheets one by one with a vacuum gripping system. Piab’s innovative and fine tuneable vacuum technology makes such sensitive handling possible.

Visors protecting people against COVID-19 from Somtech are now handled with Piab components

The fast delivery of gripping components from Piab allows Somtech to produce 56,000 visors a week with immediate effect.

With Piab’s bag grippers, Sapho increases its pace

With Piab's hybrid bag gripper, Sapho was able to significantly increase their cycle times in order to be optimally prepared for the winter business for road salt.