Powder Management in the Battery Production Process

Piab transforms battery production and recycling with its advanced vacuum conveying solutions, ensuring the purity and integrity of powdered battery materials throughout the process.

Battery materials: Purity ensured

As the battery industry evolves, material producers and cell manufacturers can gain competitive advantage by ensuring purity of the ingredients used for battery production. These battery materials are sensitive to environmental factors without the risk for cross-contamination. Mixes must be homogenous to avoid imbalances in voltage levels in the battery packs. Operator safety is also a main concern and dusting and electrical shock protection shall be in place while a system component is used. On top of all that, scale-ups might be in sight in this rapidly changing market at a fast pace and agile, modular solutions make a whole lot of difference. While all producers strive for the implementation of continuous manufacturing, a good place to start is to connect the dots in the process with conveyors designed to supply a continuous flow of the materials.

Piab's vacuum conveyors are the choice of leading material producers and battery manufacturers for their efficiency, sustainability, and reliability. We also build on our vast experience in handling metal powders within additive manufacturing where similar materials and process requirements are in place. Discover how our products can automate your battery manufacturing processes and contribute to addressing the challenges in the battery industry.

Example of battery materials where Piab vacuum conveying is the optimal solution

- Battery raw material production: graphite - green coke and carbon black

- Cathode raw materials, such as: Cobalt, Aluminium, Nickel, Lithium, Iron

- Cathode powders: Lithium Cobalt Oxide (LCO), Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2; NCA), Lithium Nickel Manganese Cobalt Oxide (NMC), - Lithium Ion Manganese Oxide (LMO), Lithium Ferro-Phosphate (LFP)

- Anode materials, such as: natural graphite, synthetic graphite, Lithium Titanate (LTO), silicon powder

- Separator foil: Plastic powders

- Electrolyte salts: Solid state electrolytes

- Recycled solids: Black mass and recovered ores

Transport battery materials: Downsides of mechanical conveying

Other conveying solutions, such as screw conveyors/flex augers, may prove ineffective for handling graphite powder due to the material's fine nature, causing it to fluidize by the pick-up point and to slide back down the tube. In general, mechanical conveying solutions often damage the battery material and are inflexible by their design.

Battery raw material entering the process with ease

Vacuum conveying is the ideal solution for unloading bulk bags or for other means of material pickup in the beginning of the battery production process. Ingredients can also be introduced to the process through a glove-box, or with the help of feed wands directly from a barrel or drum, as well as it can be emptied into a bag dump station.

Convey solids throughout the whole battery production process

Whenever you need to convey solids from one process step to another, Piab vacuum conveyors offer reliable and hygienic solutions.

Convey solids to mixing vessel, V-blender, hammer mill, jetmill, classifying, to and from storage silos, and more with ease.

Jetmills need efficient feeding, with consistent particle size distribution. The vacuum conveyor feeds the volumetric feeder on the jetmill, and a vacuum conveyor can discharge the jetmill after jetmilling. This can be completed by spheritization.

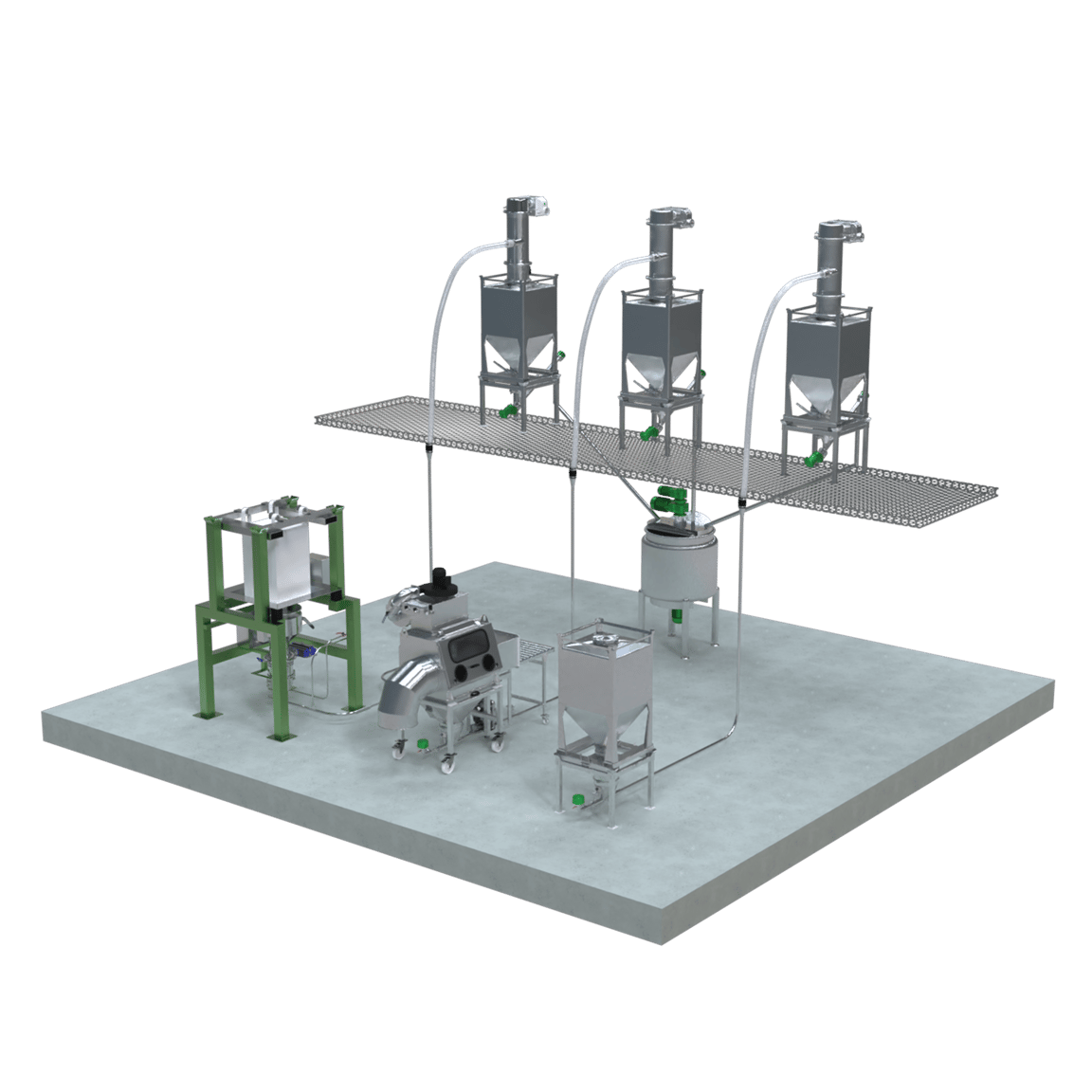

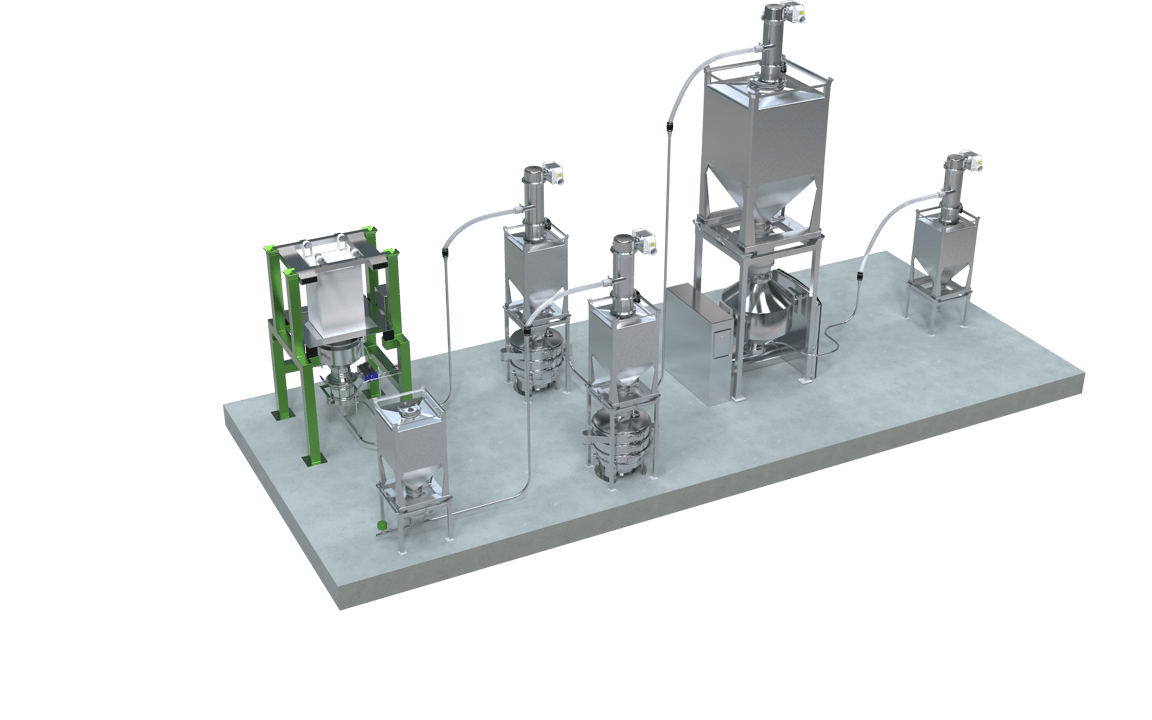

Optimizing cathode manufacturing process

In this example, ingredients are picked up with a Piab vacuum conveyor from a big bag unloader, and from an IBC (intermediate bulk container). They are conveyed to a sieve and after screening conveyed through a diverter valve to a mixer, and finally into a hopper. In this setup, the material mix reaches its destination without the risk for product segregation. Solids can also be conveyed into a slurry mixer.

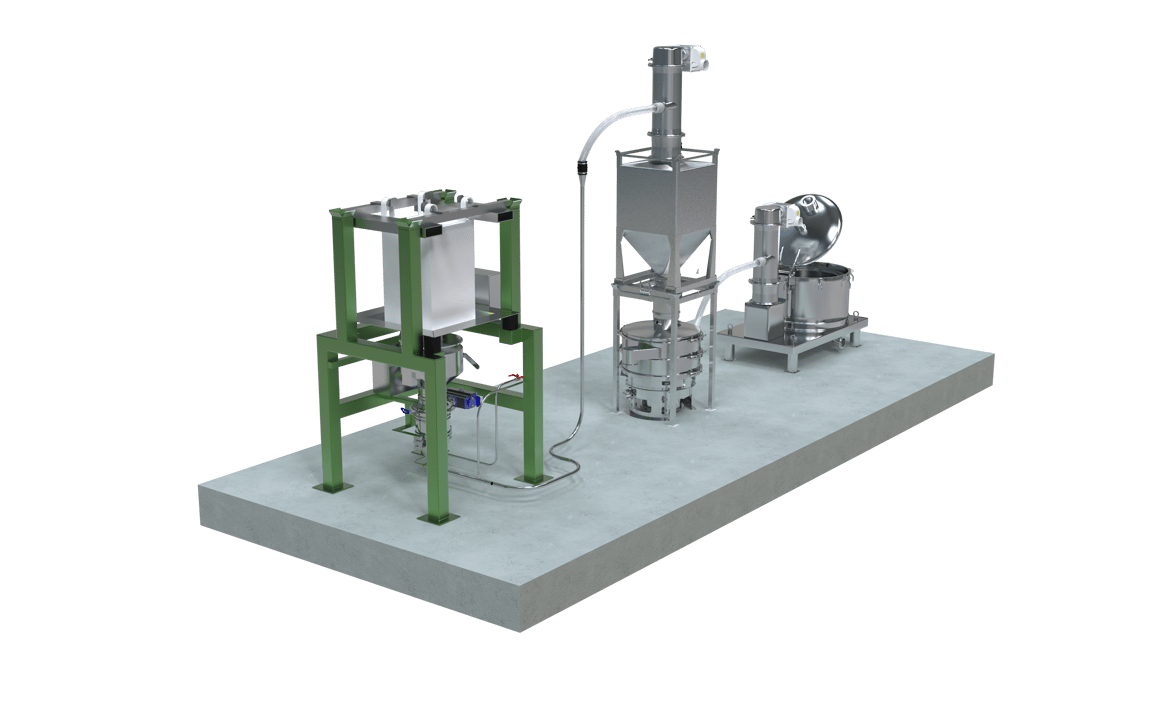

Automation of anode material manufacturing process

Piab vacuum conveyors can easily be used in the process of manufacturing anode materials as well. In this example, the material is conveyed from a bulk bag with a vacuum conveyor, through a vibrating sieve, then into a grinder. Fine graphite powders can be distributed to spheroidization and ultra-fine pulverization process steps as well – even when material integrity is inspected to the micrometers.

Vacuum solutions for battery production: Compatible with all process steps

From handling large volumes of solids (up to 14 tons/h or 30 000 lbs/h) at the process start to managing smaller, purity-critical volumes at the end, Piab offers solutions for every stage of the battery production processes. Transition pieces connecting the conveyor and the discharged/receiving equipment are available based on the application at hand.

Battery material handling: Components to rely on

Are you in need for other equipment? IB, a Brand by Piab Group has got you covered.

- Big bag loading and unloading

- IBC/container loading and unloading

- Drum loading and unloading equipment

- Big bag disposing machines

- Glove boxes

- Metering screws for continuous metering/dosing of powder

- Diverter valves

All IB products enhance your process with out-of-the-box integration with Piab vacuum conveyors.

IB equipment is available across the EU.

High demands in battery manufacturing: Why Piab vacuum conveyors stand out

Gentle and contained, avoids product damage and cross-contamination

Sustainable with a low carbon footprint

Durable and reliable resistive to abrasion and requires low maintenance while ensuring high service uptime

Scalable and seamless featuring a modular design and ensuring seamless integration to production line

Versatile and user-friendly, ergonomic and easy to set up, with a small footprint

Consistent, but flexible maintains required throughput, but can also be switched between chemistries or processes

FAQ

Yes, Vacuum conveying is ideal for conveying "black mass" and other recovered materials in battery recycling, enhancing sustainability.

Vacuum conveying is thought to damage the conveyed materials - which is easily avoided with optimized dense phase conveying by Piab.

Beyond anode and cathode materials, and solid-state electrolytes, Piab conveyors efficiently transport plastic pellets for separator production. They also tackle challenging materials prone to "ratholes" with fluidization techniques.

Yes, Piab is committed to excellence with a 5-year warranty on most products and offers global support.

Would you like to consult with an engineer?

Our team of application engineers and partners is ready to assist you in selecting the perfect vacuum conveying solution for your battery production needs. Fill out the form if you would like to get personal support.