- About Piab

- Success stories

Success stories

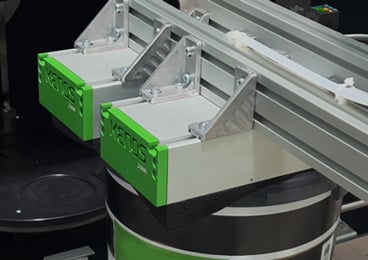

Piab and Kenos tools enable safe street lighting manufacture

Italian system integrator MVQuadro used Kenos® FlexiGrip KFG grippers and an array of suction cups from Piab to successfully assist a manufacturer of street lights.

European multinational doubles tomato sauce production with Piab-Kenos setup

Successful partnering between Piab and CFT Group, Italy, produced a vacuum-driven, tailormade solution that doubled the productivity in a tomato sauce line.

Kenos KVG grippers to improve productivity in metal sheet handling

By using Piab's Kenos® KVG grippers, Automation Technology designed and built a folding, joining, assembly, and riveting line for galvanized sheets, optimizing not only cycle times but also operator safety.

Safe palletizing of wet vehicle batteries with Piab DURAFLEX® Friction Cups

Piab's DURAFLEX® Friction Cups, plays a major part in Gruppo Esea's pick-and-place system for a leading automotive battery manufacturer.

Kenos® foam grippers to support high-speed handling of paint drums

Using Kenos® KVG120 foam grippers by Piab, Dromont Group designed a successful pick-and-place system for a paint production line at a major UK chemical company.

From Ground to 65 feet up: Piab’s Automated System Conveys Corn Seed Coating Powder up to Fourth Floor

Bayer Hungaria Kft. enjoys the benefits of Piab’s automated solution for their corn seed coating powder transportation. The implementation of Piab's piFLOW®f conveyors completely reduced the need for manual handling.

Piab carton palletizing solution improved Steelgran’s productivity by 35%

Piab vacuum foam gripper Kenos® KVGL has improved the operating cycle of end-of-line robots by 35% for Spanish company Steelgran Componentes S.A.

Increasing palletizing cycles in a food application.

MAXPRO achieved great advantages in bag handling with Piab's Kenos® KVGL gripper...

Increased productivity in the packaging and palletizing of boxes.

Using Piab's KVG and KVGL series of Kenos® grippers, Eklego designed and manufactured a state-of-the-art end-of-line system...

Automatic box palletizing in the food industry

BX suction cups made of double-strength Duraflex® in combination with Piab's COAX® vacuum generation technology have enabled Tradicional Panadera to palletize different carton formats with a single gripper.

Flexible and efficient handling of raw wood runners in a strapping system

Using Piab's Kenos® KVG grippers, Officina Meccanica Sestese SpA designed and manufactured an end-of-line packaging machine installed at a leading company in Southeast Europe, a manufacturer of components for the furniture industry.

Coffee delight thanks to Piab's vacuum conveyor at Minges Coffee Roasters

The coffee capsules and pods from Minges Coffee Roasters have been filled easily thanks to Piab's piFLOW®f...

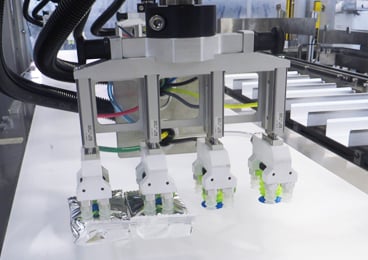

Increased productivity in forming boxes in a veterinary application

Using Piab's B52XP suction cups and piCOMPACT23 SMART pump, Cob-Solution designed and built a system to handle the picking and opening of cardboard boxes at Rao Farmaceutici, Sicilian veterinary pharmacy that is investing in e-commerce and selling throughout all Europe.

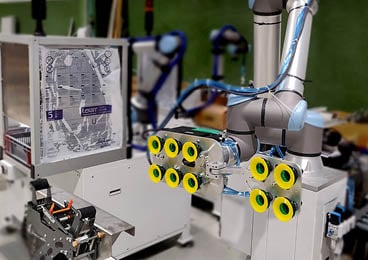

The dream team: The Wyzo sidebot combined with Piab's extremely lightweight Mini Cobot gripper (MCG)

With a maximum payload of 2.2 pounds for the Wyzo sidebot, the weight of the gripper is critical. Therefore Piab's featherweight Mini Cobot gripper (MCG) at 9.5 oz, fits perfectly.

Reinventing intralogistics

A unique, intelligent, solution that automates the intralogistics and material handling from inbound to the finished, delivered kitted items at the individual production lines has been created...

Automatic handling of packaged biscuits with Piab’s vacuum technology

Using Piab's suction cups and vacuum pumps, Tecno Pack SpA has designed and built grippers...

The dm distribution center relies on Piab suction cups

dm is currently the largest drugstore in Europe. At their distribution center a large part of the pallets is depalletized with...

Safe automatic handling of glass sheets with Piab’s vacuum technology

Forvet SpA has created end-of-arm tools that allow handling glass sheets of different sizes...

With Piab’s area gripper, the handling of furniture parts is child's play

The machine builder GO GmbH were looking for an “all-in-one” gripper solution that can be used to stack both loose and packaged furniture parts on and off pallets, as well as the pallets themselves. The solution was...

Delivering clean sugar with Piab’s piFLOW®p vacuum conveyor

To improve product quality and prevent losses India’s leading manufacturer M. B. Sugar trusts...