- News

- Flexible and safe gripping of cosmetic products with Piab

High flexibility and safe gripping in a cosmetic application with Piab's cobot gripper

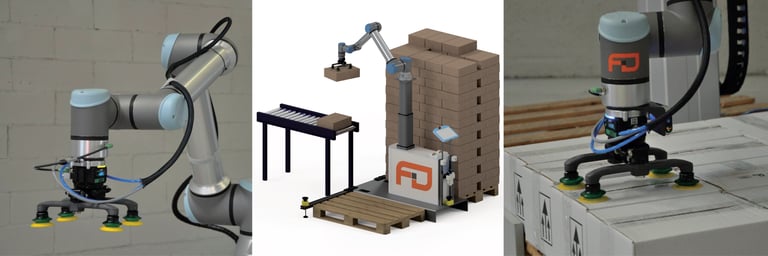

Effedi Automation chose the piCOBOT® vacuum gripper, COAX® vacuum technology and BX suction cups by Piab to handle the palletizing operations of a leading cosmetics company in a secure and efficient way.

Effedi Automation has installed a collaborative palletizing cell at an important Italian company that manufactures and packages cosmetics for third parties, using the piCOBOT® vacuum gripper, COAX® vacuum ejectors and BX suction cups by Piab.

The collaborative unit, placed downstream of a packaging machine, is characterized by its extreme flexibility, and allows very different products to be handled. This is why Effedi Automation has decided to call its collaborative palletizing cell Flexipall.

The weight of the boxes varies from less than 2 to 13 lbs. The boxes arrive already taped close. The type of carton varies depending on the end customer. Therefore, a versatile gripping system is mandatory. In addition, the items contained in the boxes are often fragile. They may be glass vials, for example, so a strong and secure gripping is essential, too.

The piCOBOT® vacuum gripper is used in two ways: as a standard end-of-arm-tool with 2 suction cups and in a special customized version with additional arms made in 3D by Effedi Automation. These arms can be equipped with 4 suction cups for handling the largest boxes or with 8 suction cups for picking up 2 of the smallest boxes at the same time. The piCOBOT® vacuum gripper is also used for handling interlayers between boxes.

The collaborative platform is mobile and compact. This makes it possible to serve 10 packaging lines, which do not all operate simultaneously.

The palletizing unit can alternate between vacuum and mechanical gripping. This allows even loose flacons to be picked up by vacuum grippers. A laser sensor monitors the gripping and any loss of the object. The collaborative unit is also Industry 4.0 compliant for data collection and transmission, enabling production to be controlled remotely.

Up to 8 cycles per minute are carried out if there is no operator in the work area. The cycle time drops to 6 cycles per minute when the operator is present to safeguard the operator and resumes full speed after the operator left the work area.

The pallets handled in the application have a limited height of less than 4.5 feet. However, the Effedi Automation palletizing cell can also handle higher heights of more than 6.5 feet.

“Companies have an increasing need for production flexibility. Collaborative robotics responds perfectly to this need, also taking into account that installation times are quick, and the investment is paid back in 12-18 months," says Federico Nardone, Effedi Automation’s CEO.

"The reliability of the gripping unit is an indispensable factor. Piab has several solutions that go in this direction and ensure highest safety standard: flexible grippers that can be easily integrated into the cobot. We have been working with Piab's Italian subsidiary for several years. We appreciate not only the company's cutting-edge solutions, but also the technical support they offer us and the possibility of carrying out tests and sizing the system at the design stage. As far as vacuum generators are concerned, we also evaluated products from other suppliers and tested electromechanical pumps. However, these were discarded because they have limited suction capacity and are not reliable for handling porous and highly variable products. To this end, the COAX® vacuum technology, integrated in the piCOBOT®, proved to be much more efficient," adds Federico Nardone.

Piab’s piCOBOT® vacuum gripper is light, powerful and adaptable, and allows secure gripping of the material being handled, even of tall and heavy objects. The standard version is available with one or two suction cups or with a customized vacuum gripper. It is capable of picking up one or two objects simultaneously, even with different shapes and structures. With the piCOBOT® vacuum gripper, companies investing in a cobot can make full use of its load capacity and improve their return on investment.

Piab's BX suction cups are developed for multi-purpose applications, where some level compensation is required.

Piab's COAX® multistage vacuum ejectors minimizes energy consumption, while offering a safe and fast gripping due to their high initial flow rate. The vacuum pump can deliver high performance even with low or fluctuating feed pressure.