How to choose the right filters for a vacuum conveyor?

This article is a tribute to vacuum conveyor filters! Read more to figure out how they emerged in time following the needs and to learn which parameters affect their function.

Jump ahead

The main filters

The filters are the lungs of the vacuum conveyor. They clear out the dust that would otherwise contaminate the manufacturing facility and the lungs of the operators. They also make sure to keep the vacuum pump operational, and they ensure compliance with the rigorous and ever-changing safety regulations and other demands on health and safety within various processes. The position of vacuum conveyor filters varies - from inside the conveyor body to being placed externally in air inlets to ensure compliance with higher demands.

Vacuum conveyors provide a contained alternative to bucket elevators, screw conveyors, or other mechanical solutions to transfer powders and granules. Still, expectations and requirements have changed a lot throughout the past decades. As a response, the mounting of filters became easier, the filtration grade and air permeability increased, and the design became modular. Compared to the one-filter set up in a 1991 Piab vacuum conveyor series, devices today feature 1, 3, or 7 filters, depending on the conveyed volume or the conveyor size.

Also, the introduction of the built-in air shock assembly made the conveyors easier to set up and clean, leading to a longer filter life and higher production capacity due to less need for cleaning filters during production. The vacuum filter shock system today is built into each Piab vacuum conveyor, integrated with the top lid of the conveyor. These devices have a cyclic operation, and the conveyed material is ejected by the end of each period to a receiving vessel or device. When a period is over, the filter gets cleaned by a filter shock. Each filter has its own filter shock for the highest level of efficiency.

Location of internal filters

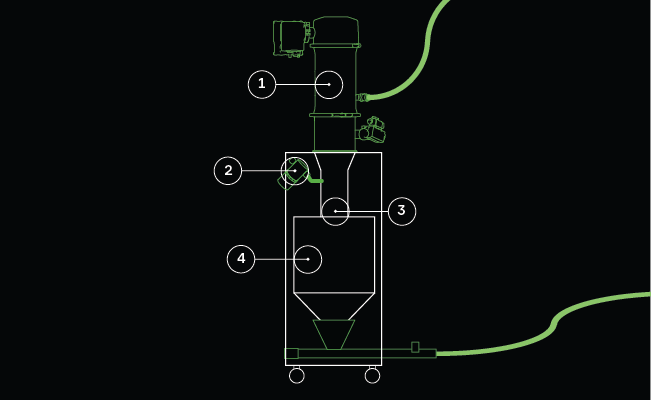

Filters are used in many different locations in a vacuum conveying system. The main ones can be found in the conveyor body (2), and they ensure the proper basic functioning of the conveyor: when air is added to the conveyed bulk powders, granules, or small parts, the air has to be removed and filtered before it flows out to the surrounding atmosphere. They are cleaned with filter shock (1).

Cleaning with filter shock

The filter shock system consists of one tank per filter that creates the filter shock by the end of each vacuum conveying cycle. During operation, the filter collects dust on its outer side while the vacuum pumps pull the material toward the filter. But during the air shock, the opposite happens: the air is blown from the inside out of the filter in a fierce shock which makes the filter release the material.

Other ways to clean internal filters

Most Piab filters can be cleaned with dry cleaning by repeated filter shocks and also by gently brushing with a non-abrasive brush or camel hair brush to avoid damage to the membrane. Wet cleaning of filters is also possible: the filter can be rinsed using an indirect water spray with a standard low-pressure water hose (maximum 1 bar) while still mounted on the filter support. After cleaning, the filter should be hung to allow drying in an open position. Wet In Place method can also be used on them– some filter types just need more time to dry after they have been cleaned due to a larger filtering surface.

We have continuously developed the filter range and our vacuum conveyors based on our users’ needs. I have worked at Piab for 29 years, and I am glad to work for a company that invests heavily in R&D. It is fantastic to see the evolution of our products. They have become easier and easier to set up and operate, as well as smarter. The modular design makes it easy to scale the capacity up and down and to accommodate different material types and changeovers.

– Tomas Tiger, Global manager of Application & Customizations

Sizing and maintenance

Modularity for easy maintenance

Piab’s standard filter range can filter out small particle sizes from 0.5µm since 2000 – development has made it possible to convey a wider range of materials and to comply with stricter regulations.

Modularity is one of the cornerstones of product development at Piab, which allows for a high grade of flexibility. Maintenance of the filters is easy as they are threaded to the conveyor body or pressed onto a metal plate, making it fast to assemble and disassemble without the need for any tools. Nevertheless, regular replacement of the filters is inevitable. Therefore, we recommend always stocking up with spare parts. When spare ones are not in stock though, Piab normally ships commonly used parts, such as filters, within ten days. (Local terms and conditions apply. Please consult with your nearest Piab representative or partner.)

The frequency of filter replacement varies depending on the industry, the conveyed materials, the capacity, and other factors. As an example, and as a rule of thumb, we can estimate a 6-monthly replacement time in the pharmaceutical industry as the devices are cleaned and sterilized relatively often. Such frequent replacement periods also occur when ceramics are conveyed because of the erosive characteristics of the material. In this case, shorter filters should be in place to minimize the contact between the incoming material and the filter. Otherwise, filter life can be much longer, but how often the filters have to be changed depends on the conveyed material, the system’s capacity, the filter type, and even environmental factors, so there is no ultimate recommendation that applies to all cases. Our recommendation is to replace filters yearly on average.

What to consider when choosing filters?

Several factors affect which filter should be chosen for an application.

Particle size is important because finer powders need a bigger filtering area to ensure the maximal conveying ability. And the question is also how rigorous rules you must comply with.

Hygroscopic materials are often sticky and have a higher fat content than 25%. Higher humidity level increases the hygroscopic characteristics, too - think about how sugar gets sticky in a wet atmosphere, like in the tropics. As a rule of thumb, if we can make a snowball with the material in our hands, it may be considered a caking or bridging material, which forms material bridges during operation. Generally, the smaller and smoother the filter area, the easier it is to handle bridging materials, as they have fewer possibilities to stick to the filter surface.

On the other hand, a smaller filter area can result in a pressure drop around the filter, leading to decreased conveying ability. The pressure drop is compensated by the higher air permeability of the filter material and an easy way of cleaning by air shock pulses.

Apart from material characteristics, the decision on filter types depends on the pipes, too. The pump capacity and filters must be aligned with the pipe length. The longer the conveying distance (and the pipe length), the bigger pump has to be applied to carry the same amount of powder. Higher capacity need implies a larger pipe diameter. The decision is also affected by the number of bends on the pipe.

Second-stage filter units with ULPA filter

When hazardous materials are conveyed, the filters can be completed by second-stage filter units, which work even with extremely small particle sizes from 0.2 µm. Featuring ULPA filters, these second-stage filter units are suitable for particularly fragile products in general. They are placed between the conveyor body and the pump.

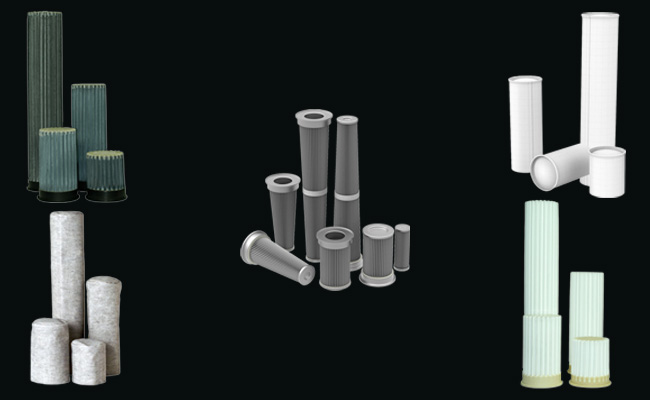

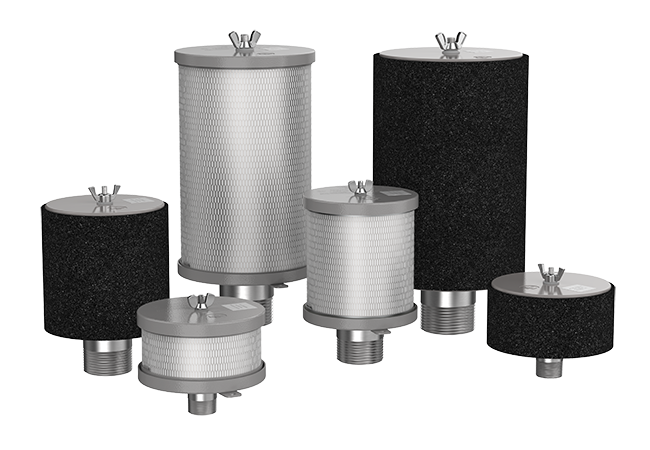

Overview of the main filter types at Piab

Textile, pleated rod, pleated stainless steel, and pleated filters are placed inside the conveyor body. Piab internal filters were designed to ensure maximal security and capacity simultaneously so that you can breathe in calmly at your production line. Click here to reach a summary of the main filters with a comparative table:

Air inlet filters

Air inlet filters prevent atmospheric and air-carried dust and particles from entering the conveying system through the adjustable air inlets of the feed adapters, resulting in contained material transport through the system. At the same time, they prevent the conveyed material from coming out from the feed adapters' adjustable air inlets, e.g., when fluidization is used. When an Air Inlet filter is added to Piab’s feed adapter, it prevents cross-contamination. They are compatible with all Piab feed adapter types and are also recommended when venting holes are used in the vacuum conveying setup. Air inlet filters have a weather hood to increase their lifetime.

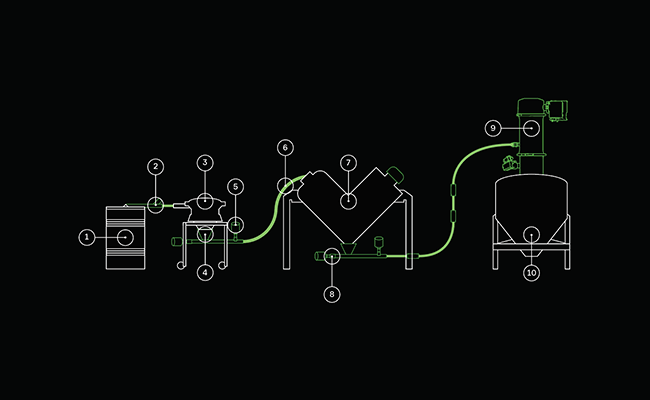

Placement of the air inlet filters

In this application example, the material is conveyed from a barrel (1) with a feed wand (2) to a sieve (3), then to a V-blender (7) through a hose (6), and goes further to a silo (10), having a vacuum conveyor on top (9). The (5) air inlet filters are placed on the air inlets of the (4) feed adapters. When an air inlet filter is connected to the feed adapters, a specific (8) Reducer must be applied. Cross-reference tables are available in the respective manuals of the air inlet filters to choose the right elements for your setup. Replacement elements are also available for all air inlet filter types and sizes.

Select the appropriate air inlet filter

Consider the compliance level of your facility. The Standard air inlet filter (carbon steel) is suggested when requirements are lower and non-conductive materials are conveyed. When higher demands apply, such as antistatic properties are needed, or where acid/corrosive resistance is a must, the Antistatic air inlet filter (SS316) is advised.

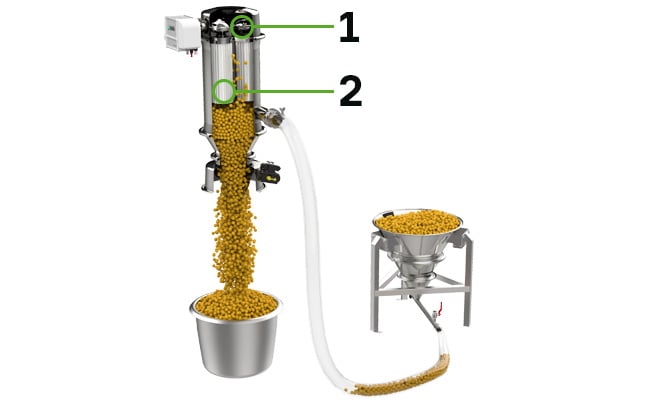

How to use vacuum filters?

The so-called vacuum filters (2) are recommended when there are lower hygienic requirements in the facility and no food requirements or antistatic properties are needed. They are lightweight, made of plastic, and have a filter grade of 5-10 µm.

They may be used where extra venting is required (due to material characteristics or the process setup). One example is to cover the venting hole on transition pieces (3) under the conveyor body (1) when the material is emptied into a silo/hopper (4) or other equipment. In this case, venting is needed to ensure a smoother material transition as the vent evens the pressure.