Coffee Conveying

Handling coffee requires precision to maintain its delicate aroma throughout processing. Piab's advanced coffee conveying technology ensures the seamless transportation of green coffee, roasted beans, and ground coffee, preserving their unique characteristics at every stage. Our innovative conveyors streamline operations for both small-scale and large-scale coffee production, offering efficient automation solutions.

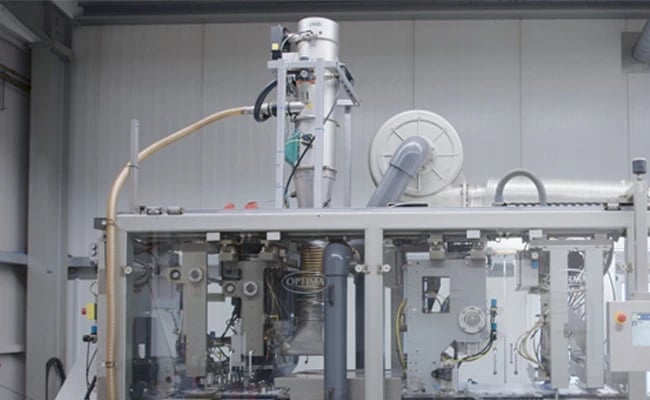

Coffee conveying at Minges

The Minges coffee roastery uses Piab vacuum conveyors to preserve the aroma of their products and increase productivity and efficiency at the same time. The Piab coffee conveyors fill their packaging machine and capsule filling machine, while suction cups are used to move the finished pods and erect the packing boxes.

Charging equipment with coffee

Filling the packaging line with coffee beans or ground coffee has never been easier. Piab's coffee conveying technology ensures a low-maintenance alternative with a small footprint to overcome vertical lifts of materials while preserving product aroma. Coffee beans stay intact throughout the process, ensuring that ground coffee reaches its destination without contamination.

The importance of ergonomics

Effective coffee handling is crucial to prevent physical strain and injury among workers. Manual handling of coffee poses risks to productivity and quality due to the potential for errors and inefficiencies. Additionally, manual handling can be time-consuming and labor-intensive and may lead to contamination, as workers may inadvertently introduce foreign objects or bacteria into the coffee during the handling process. Utilizing advanced coffee conveying technology and conveyors optimized for coffee handling can mitigate these risks and ensure a smooth and efficient coffee conveying system.

Conveying of coffee: a delicate process

Micro roasteries and large-scale industrial facilities share the challenge of transferring coffee from one process step to another. Yet, it is very common to use practices that may affect product quality negatively. Choosing the right method for coffee conveying is crucial to preserve the aroma of the coffee, and it is often required to prevent coffee from interacting with atmospheric air. Piab vacuum coffee conveyors operate both in semi-closed systems using atmospheric air and in closed loops with nitrogen gas replacing oxygen.

Vacuum conveying is thought to damage the beans - which is easily avoided with our proprietary piGENTLE® technology that uses dense phase conveying.

Using vacuum conveyors may also solve ergonomic issues in the facility by avoiding manual coffee handling and overcoming vertical lifts with flexible hoses. The lack of moving parts contributes to minimal maintenance needs and easy equipment cleaning.

Piab coffee conveyors can also handle coffee, sugar, and other additives in instant coffee production.

Piab vacuum conveyors are used by small and large coffee producers worldwide. Our products comply with food standards, and we also provide global support and help you choose the right coffee-conveying equipment for your needs through our application engineers and partners.

We wanted a conveyor to fill the pod production system that effectively does its job, so we don't need to worry about this part of the process. We were particularly pleased by the simple and robust design of the Piab piFLOW®f.[...] Replacing the old solution with a Piab vacuum conveyor has helped us improve product quality.

piFLOW®p feeding a sachet filling machine

Piab piFLOW®f filling a packaging line

Benefits of conveying with Piab

Preserve the aroma in transfer

Using a closed system to transfer coffee reduces the possibility of aroma loss in the process.

Increase productivity

Feeding of the roaster, the grinder, the capsule filling machine, or the packaging machine can be automated easily.

Compact design

The compact design has a small footprint and takes less space than, for example, a screw conveyor or bucket elevator.

Compliant coffee conveying

All Piab equipment with food contact is EC, FDA, and USDA certified. We also offer ATEX-certified equipment.

Explore more

Products

Do you want to know more about our vacuum conveyors for your coffee production?

Find out what applies to your raw materials and products! Fill in the form to get free, personal advice from our engineers to find the best solution for your needs.