Snack Food Conveyors

Designed specifically for handling snacks like almonds, nuts or conveying seasoning powder, our systems ensure optimal efficiency and product integrity. With advanced engineering and innovative technology, our conveying solutions streamline your operations while maintaining the highest quality standards.

New flavors: Demands of the snack food industry

In a market where customers increasingly seek new flavors and various snack options, the snack allergies and sensitivities, through fluctuating production demands to the need for precision handling of various products, manufacturers must navigate a complex landscape. Also compliance with stringent food safety regulations and quality standards is a must for snack food manufacturers.

In today's fast-paced snack food market, a high demand for efficient handling and rapid production is therefore critical. Piab's snack food conveying systems are engineered to support these high demands while providing the utmost care for your products. Our vacuum technology enables versatile and efficient transport of various snack items, ensuring minimal product loss and breakage. With Piab, you can confidently scale your operations, meet market demands, and change processes to satisfy your customers needs. industry operates under unique challenges that require specialized equipment. From food aller

Conveying various snacks to different manufacturing processes

Snack products vary in size, shape, and texture, requiring flexible and adaptable conveying solutions to maintain product integrity and ensure seamless transitions between processing steps. Whether transporting delicate almonds, gummies, or dense nuts, our systems ensure gentle handling to prevent damage or breakage and allowing snacks to be easily moved across multiple production lines, including roasting, coating, seasoning, and packaging processes.

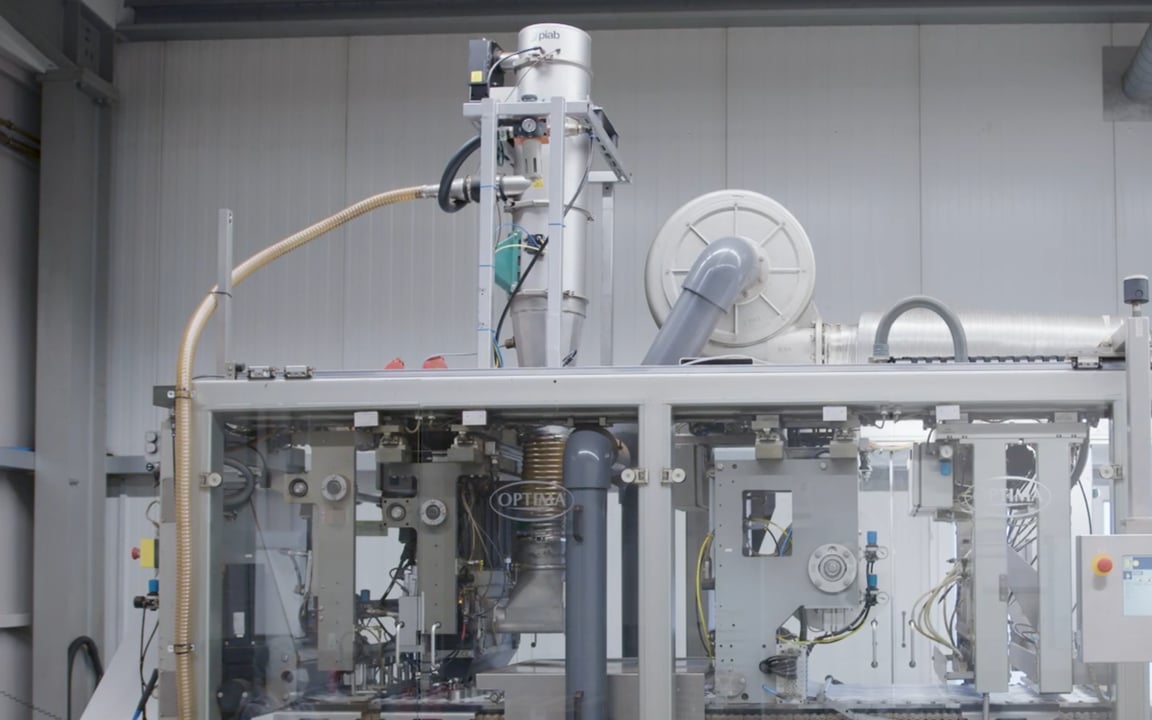

Seasoning of products: Vacuum conveying of seasoning powder

Fine powders like seasoning can be difficult to transport due to their lightweight, dusty nature and tendency to stick to surfaces or clump together. Our systems are designed to address the common issues associated with seasoning powders, including dust control, consistent flow, and accurate dosing. Vacuum conveying reduces the risk of powder leakage and contamination, ensuring that production lines remain clean and compliant with FDA standards. By maintaining consistent airflow and minimizing powder buildup in the snack food conveying system, our solutions help you achieve uniform seasoning distribution on snacks like chips, nuts, pretzels and popcorn.

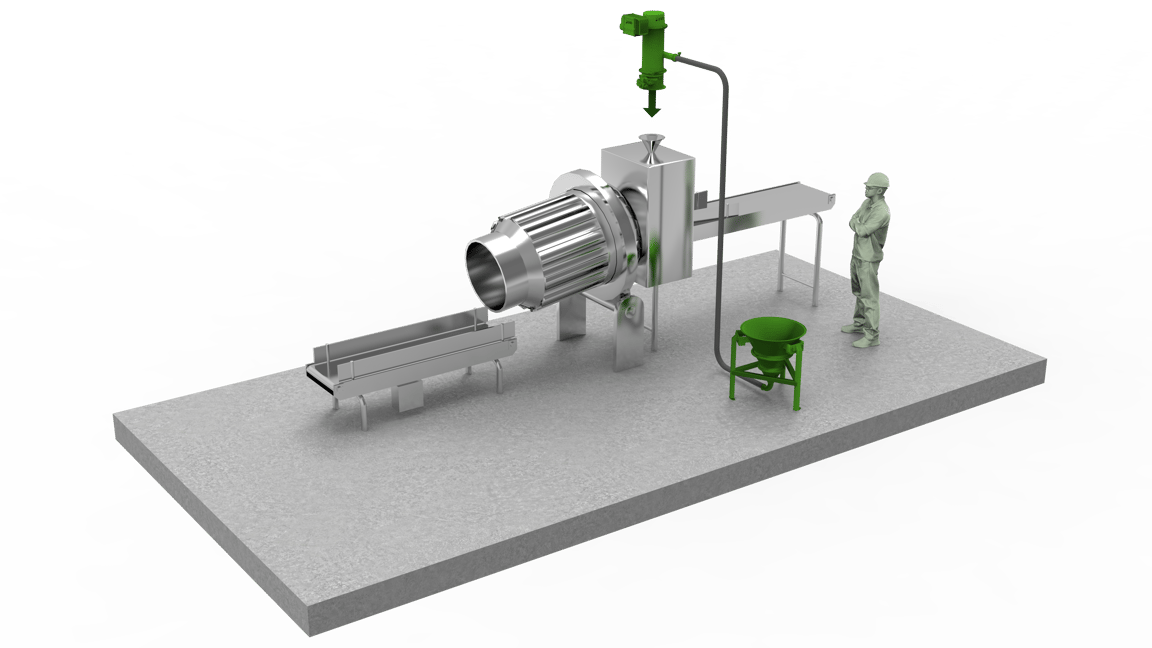

Screw conveyors vs. vacuum conveying in the snack food industry

Screw conveyors, along with overpressure and vacuum systems, have traditionally been used for transferring seasoning powder and other ingredients. However, screw conveyors have several drawbacks, including a less hygienic design and operation, challenges in achieving thorough cleaning, and the necessity for ongoing maintenance. Additionally, screws require a larger footprint within the manufacturing facility. On the other hand, overpressure systems, often referred to as pod systems, struggle with transferring bridging spice mixes in a controlled manner and may cause spice emissions in the event of a leak.

Vacuum conveying: Snack food conveyors by Piab

Vacuum conveyors are a vital component in overcoming the challenges of snack food manufacturing, offering solutions that improve product handling, enhance workplace safety, and support efficient, flexible production.

Benefits of conveying snacks and ingredients with Piab

Piab’s snack food conveyors are designed to handle certain delicate snack foods with care, reducing the risk of breakage and ensuring product quality throughout the process.

Our systems optimize material flow, significantly improving the efficiency of your snack food production line. This increased throughput allows snack manufacturers to meet high demand with minimal downtime.

With controlled, dust-free vacuum conveying, our systems work through the stickiness of seasoning powders and reduce product loss, guaranteeing that the seasoning process is efficient, clean, and repeatable.

Easily adjust production volumes with Piab's vacuum conveyors, enabling snack food manufacturers to scale operations according to fluctuating market demands without compromising performance.

Our snack food conveying systems are meeting the FDA standards and maintain the highest demand on food safety. Piab’s vacuum conveyors are easy to clean and reduce the risks of cross-contamination.

Explore solutions in Food manufacturing

FAQ

Vacuum conveyors are not typically used for conveying fragile items like chips, as the chips could break during the process. However, vacuum conveyors are ideal for conveying the seasoning used for chips. They ensure the seasoning is handled gently and efficiently, minimizing dust and maintaining hygiene.

Do you want to know more about our vacuum conveyors for your snack food production?

Find out what applies to your raw materials and products! Fill in the form to get free, personal advice from our engineers to find the best solution for your needs.