Pneumatic Conveying of Sugar, Powders, and Candies

The confectionary, candy, and baking industries handle a wide variety of products under rigorous quality requirements. Piab vacuum conveying systems provide dependable and effective solutions that enhance material handling in numerous applications.

Sugar conveyor that enhances efficiency in production

Piab vacuum conveyors are tailored for the confectionery industry, providing solutions that emphasize gentle conveying, hygienic design, and user-friendly operation. Our sugar conveyors are particularly suitable for handling delicate materials.

The piFLOW® range, with its compact design, addresses the industry's need for space efficiency and adaptability to frequent layout changes driven by consumer demand. The conveyors' low-noise and contained operation contribute to a healthier work environment, essential in food production settings. The piFLOW®t model, in particular, effectively conveys delicate products like coated candy and chewing gum with minimal breakage.

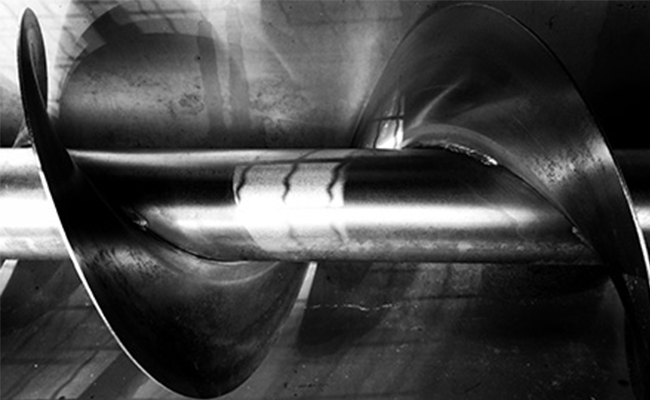

Sugar screw conveyor vs Vacuum conveyor: Main differences

When it comes to transporting sugar or other granulated materials, choosing the right conveyor system is crucial for efficiency and productivity.

What are the main differences between sugar screw conveyors and vacuum conveyors?

Mechanical conveying

Vacuum conveying

! Unsuitable to convey delicate materials (will result in breakage and deterioration).

! Less hygienic design and operation.

! Difficult to clean, requires continuous service/maintenance.

There are several options of a mechanical sugar conveyor; belt, screw, and bucket principles differ from one another but all of them yield to pneumatic technology. A vacuum conveyor can address the specific needs of your operation, offering tailored solutions to your manufacturing processes when you need a sugar conveying system.

Advantages of a sugar handling system by Piab

Vacuum conveying systems can be used in various applications across the confectionary industry. Main reasons to choose Piab sugar conveyor are:

Versatile ingredient handling

Efficiently transport ingredients such as sugar, small granules, and cocoa powder to mixers and processing equipment with very limited or even nonexistent breakage of the conveyed product, ensuring precise and consistent blending.

Enhanced dust control

Provide contained conveying solutions for dusty materials, improving air quality and reducing health risks in the production environment.

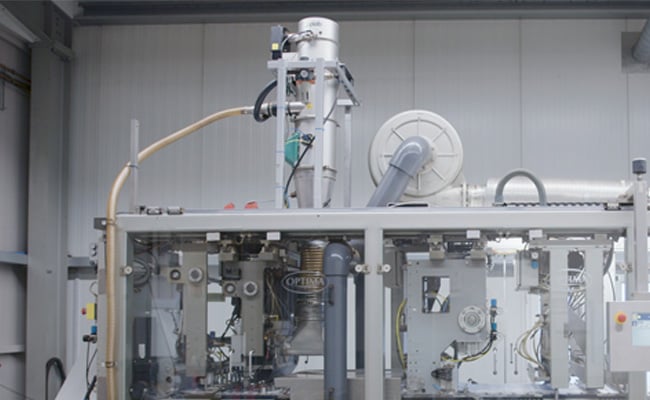

Deliver to packaging lines

Deliver finished products to packaging machines, optimizing the packaging process and reducing manual handling. End products prone to breakage shall require proof of concept. Contact our engineers to learn more!

Hygienic design and compliance

Our sugar conveying systems feature a hygienic design to prevent contamination and ensure safety. Made from easy-to-clean, corrosion-resistant materials, they meet health regulations and enhance sanitation with smooth surfaces and minimal crevices.

Energy efficiency

Piab sugar conveying systems are energy-efficient, using compressed air only during suction. This optimization reduces energy consumption, supporting sustainability and lowering utility costs.

Flexibility and scalability

Piab sugar conveyors offer flexibility and scalability, allowing easy adjustments or expansions to meet changing production demands. Ideal for businesses aiming to grow or diversify product lines without extensive infrastructure reconfiguration.

Certified quality worth your choice

Quality is our first priority. Our commitment to quality is evident in both the EU 1935 and FDA certifications, which are crucial for industry compliance. Furthermore, Piab equipment is available with ATEX certification to ensure safety across various operational environments, covering the full spectrum of necessary certifications.

In industries dealing with sensitive materials that pose health risks or are vulnerable to humidity and contamination, selecting the appropriate conveying equipment is crucial. Obtaining proof-of-concept from our engineers guarantees that your materials are conveyed safely, hygienically, and efficiently. Watch the video to see how our Customer Experience Centers function.

Safe pneumatic conveying system for sugar and other ingredients

Our versatile piFLOW® sugar conveyors enable quick changeovers and simplified cleaning, making them an ideal solution for sugar pneumatic conveying, as well as transferring other materials within confectionary industry:

- Cocoa powder

- Chocolate chips

- Malt

- Flour

- Milk sugar

- Chewing gum powder

- Finished candy products

Contact us and get instant help finding the optimal equipment tailored to your production specifications.

Explore products for your vacuum conveying needs

Let’s find the right sugar conveyor for your production needs

Fill out the request form, and our engineer will provide you with a free consultation shortly.