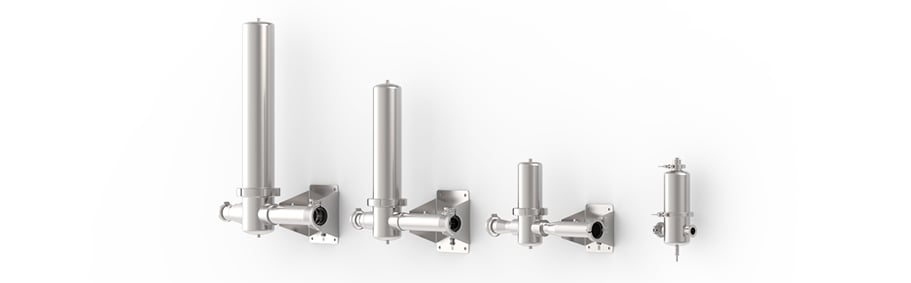

Pharma Automation: Conveyor Systems for Pharma Industry

Piab revolutionizes pharmaceutical manufacturing with its advanced vacuum conveyor solutions, ensuring the safety, purity, and efficiency of powder handling processes from start to finish. With advanced technology and rigorous testing, we provide solutions that enhance efficiency and meet the evolving needs of pharmaceutical manufacturing.

The usage of pharmaceutical conveyors

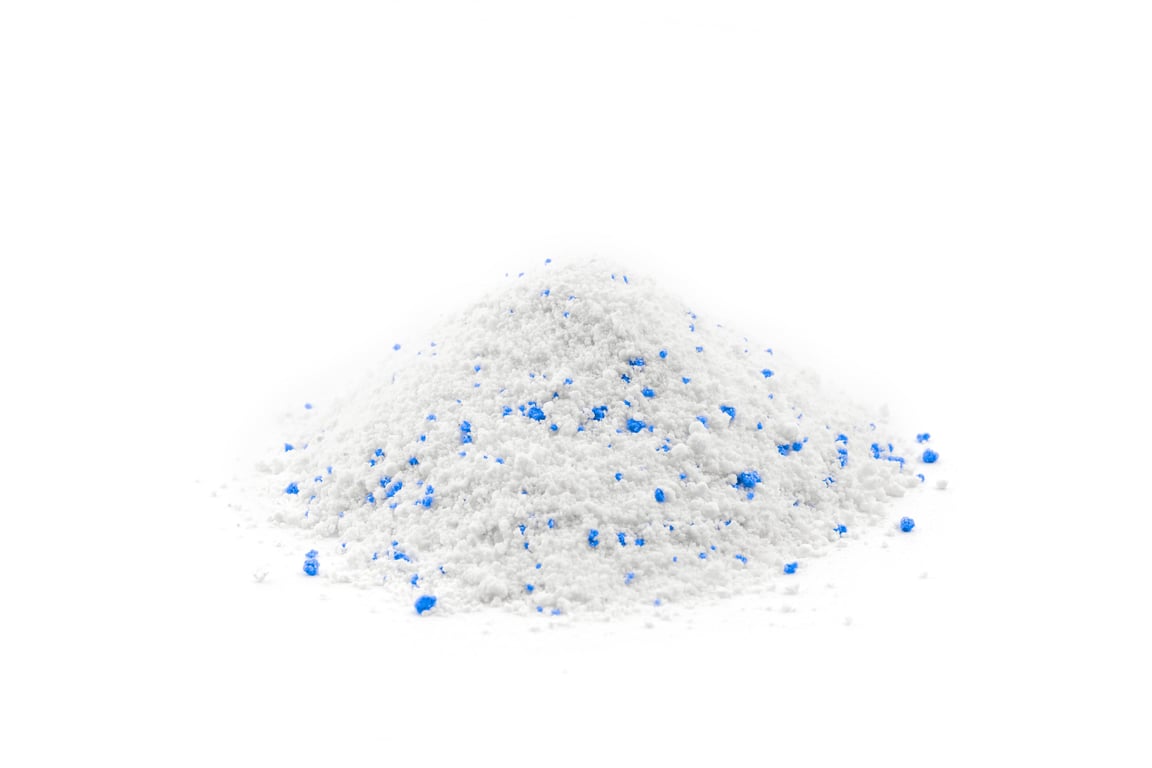

Powder

In pharmaceutical manufacturing, powder handling can be achieved through either manual processes or automated solutions. Piab’s pharmaceutical conveyors are specially designed for powder handling pharmaceuticals, addressing the challenges by providing efficient and hygienic powder conveying pharma solutions. Our customized systems ensure safe, enclosed powder conveying of pharmaceuticals that maintain consistent flow and minimize contamination from start to finish, enhancing both process efficiency and product quality.

Tablets and capsules

The powder handling pharmaceutical conveyors of Piab are designed for powder handling tablets and capsules, which offers a range of applications. Our conveyors provide processes like capsule filling and feeding tablet press operations, ensuring precise and consistent handling. Our solutions enhance the efficiency of tablet press operations and provide a safe, enclosed system that maintains product integrity and compliance throughout the entire production process.

Pharma automation: Steps in the pharmaceutical manufacturing process

The Piab vacuum conveyors for powder handling in the pharma industry are highly effective for key formulation steps. Connect the dots in your production line with the right powder transfer equipment!

Feeding material: Transport powder to tablet press and other units

During pharmaceutical manufacturing, a powder mix is transported to and from sieving units, milling and grinding machines, or blender and mixer. Piab vacuum conveyors effectively replace manual feeding of your machines or any other lifting solutions by ensuring a quick filling and emptying process. As an example, feeding the tablet press is one of the applications where Piab vacuum conveyors make a massive difference in productivity, efficiency, and safety.

Conveying powder from barrels and drums in a closed system

When working with hazardous materials in the pharma industry, it’s crucial to minimize employee interaction as much as possible. Emptying barrels and drums is not only manually intensive but employees are often exposed to the dangerous content. With our vacuum conveying systems, we ensure an enclosed system, reduce the risk of exposure to employees, and replace manual work with vacuum technology. Other material pickup points, like bag dump and feed stations, are also available.

Capsule filling

Capsule filling is often one of the last steps in pharmaceutical manufacturing. In this step dusty powder is transported for capsule filling by manual handling techniques. Piab’s vacuum conveyors can effectively replace manual powder handling since powder pick-up is possible from a barrel or container. This helps to ensure better productivity and safety of your employees due to a reduced risk of exposure to hazardous materials.

Packaging of powder, tablets and capsules

Packaging is the last step in the manufacturing process and is usually done with many employees present, which means that low noise levels are critical to ensure a safe working environment. Piab vacuum conveyors are well suited for feeding packaging machines because of low noise levels and are designed with an enclosed system ensuring employee safety due to removing any dust particle exposure during the packing process.

Reclaim of powder and damaged tablets or capsules

The possibility to automate the reclaim process of powder, damaged tablets and capsules can increase efficiency of scrap handling as well as reduce employee exposure to hazardous materials, e.g. toxins and allergens. Piab vacuum conveyors can move damaged products via an enclosed system to scrap handling thus eliminating dependency on operator interaction.

Piab’s solution for the challenges of the pharma industry

Pharmaceutical manufacturing faces numerous challenges, from ensuring product integrity to meeting stringent regulatory requirements. The main issues in the powder handling pharma industry include product segregation, cross-contamination, discontainment, and maintaining clean room standards. Addressing these challenges requires innovative solutions that enhance productivity while ensuring quality and safety, which is what Piab has the solution for.

The downsides of manual handling

Manual handling is still prominent in pharmaceutical manufacturing - in batch manufacturing, operators often charge equipment by hand. This implies environmental health and safety concerns, but it might also harm product quality and productivity. Vacuum conveying allows for process automation to avoid these issues.

Conveying pharmaceuticals: Downsides of mechanical vacuum pumps

Pneumatic vacuum systems, powered by compressed air, are smaller, lighter, and more energy-efficient than mechanical pumps, which run on electricity. They require less maintenance and offer intermittent operation to make it easier to handle temperature fluctuations. For handling pharmaceuticals, vacuum conveyors minimize product degradation and reduce heat, noise, and contamination. This makes them ideal for efficient and clean conveying processes.

Eliminating cross-contamination

Cross-contamination happens when conveyed materials are exposed to their environment, causing a loss of properties and diminished end-product quality. This is especially critical for APIs, which are sensitive to environmental factors. Piab’s vacuum conveyors, designed for powder conveying pharmaceuticals, operate in closed systems to effectively eliminate the risk of cross-contamination, ensuring high-quality products.

Preventing discontainment

Discontainment occurs when materials are conveyed in open systems, exposing operators to potential hazards and posing occupational health and safety risks. Occupational Exposure Limits (OEL) and Occupational Exposure Bands (OEBs) define permissible exposure levels and toxicity. Piab's vacuum conveyors for powder handling pharma operate in closed systems, eliminating cross-contamination risks and protecting the environment and the product.

Meeting cleanroom standards

Piab’s vacuum conveyors for the pharma industry are designed to meet strict clean room standards, featuring highly effective second-stage ULPA filters to capture particles larger than 0.5µm. Our remote pump solutions keep the clean room free of contamination by operating the pump outside the room and using pump exhaust recirculation to maintain air purity.

Avoiding product segregation (separation of mixes)

In pharmaceutical manufacturing, where active ingredients and excipients are used, precise ingredient amounts are essential to prevent product segregation. Piab’s vacuum conveyors address this challenge by utilizing slow-speed, dense phase conveying, which maintains a high particles-to-air ratio and minimizes segregation. This technology is particularly effective for pharma powder handling used to produce tablets. Additionally, Piab tests materials and evaluates its conveying systems to ensure optimal performance for each unique mixture.

The expanding pharma market: Adapting to continuous manufacturing

The pharma industry is rapidly advancing with a shift towards continuous manufacturing, driven by the need for higher efficiency, lower environmental impact, and improved product quality. As regulatory standards tighten and market demands evolve, pharmaceutical manufacturers must adapt to new technologies and streamline production processes. To stay competitive, companies in the pharma industry need to enhance productivity, reduce manual labor, and minimize product waste. Continuous manufacturing solves these challenges by optimizing material flow and integrating process steps.

Using Piab’s equipment, manufacturers in the pharma industry can improve efficiency and achieve higher quality.

High demands in the pharma industry: Why Piab vacuum conveyors stand out

Safe and Hygienic

Prevents product loss and contamination

Compact and Versatile

Integrates seamlessly into pharmaceutical production lines

Protects the Products

Safeguards sensitive pharmaceutical materials

Easy Maintenance

Low maintenance with no moving parts for pharmaceutical applications

Energy Efficient

Piab technology reduces energy use with a small footprint

Adaptable and easy to use

Features an ergonomic design and straightforward setup

FAQ

Our vacuum conveyors are designed to meet the stringent requirements of the pharma industry, offering excellent containment, easy cleaning, and compliance with regulatory standards.

With Piab vacuum conveyors you get higher productivity, less downtime, improved product quality and compliance with safety for employees.

Get help choosing your ideal conveying equipment!

Find out what applies to your raw materials and products! Fill in the form to get free, personal advice from our engineers as well as comparisons with other technologies to find the best solution for your needs.