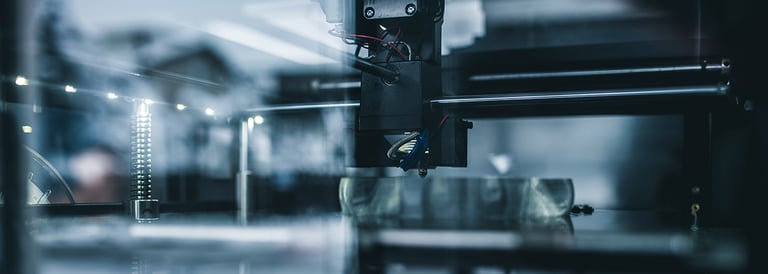

Automating powder handling in the Additive Manufacturing industry

The Additive Manufacturing industry has so far focused on the printer technology. With its high growth rates and increasing capabilities, automating metal powder handling is key to establish the technology as a standard process in the medical, aerospace, and automotive sectors – its largest user groups. Piab’s vacuum conveying powder handling solution fills this gap with tested and proven systems.

With an estimated expected compound annual growth rate (CAGR) of 25% until 2023 Additive Manufacturing is one of the fastest growing technologies impacting the industry today. The technology gives clear advantages for the user related to design and manufacturing of complex parts, prototyping and small series runs, so far mainly for lab and R&D purposes. However, as the technology matures, so does the user and with that, demands on safety, process reliability and quality are increasing.

As the printing machinery driven development lacks a holistic approach, surrounding process steps and technologies need to be developed or adapted, where possible, and integrated into the total process flow. A major process contributing to the long-term success of Additive Manufacturing, particularly in the field of metal parts production, concerns metal powder handling.

The specifics of metal powder handling

Metal powder handling requires special attention due to its hazardous potential for employees, its explosiveness, and its value as a high price ingredient.

Exposure to metal powders poses an extremely high health risk to employees especially when breathing it into the lungs. Additionally, lifting and handling heavy containers or barrels can result in serious back or shoulder strains.

As metal powders can be atmospheric explosible materials, ATEX requirements apply to protect the facility. Further construction considerations help to minimize the risk of equipment implosion.

As the pure metals or alloys thereof are expensive ingredients ensuring their purity during production by avoiding any cross contamination or segregation and reclaiming unused material from the process are key for an economically viable set-up.

The solution to all three issues is a closed and automated metal powder handling process based on vacuum conveying technology. A technology which has already proven to be an optimal solution in the pharma and chemical industries, which face similar material handling challenges.

Piab’s vacuum conveyors meet the requirements of low building height, ease of cleaning, low noise levels and ATEX certifications in the Additive Manufacturing industry. The contained and enclosed system minimizes the spread of the dust during transportation of the material, minimizing the exposure to hazardous dust, making Piab’s vacuum technology ideally suited to transfer metal powders. Moreover, it keeps the material from contamination with impurities from other particles, meaning that the structure of the metal powder units remains, and proper quality of the 3D printed object is fulfilled.

As a global market leader in vacuum conveying with extensive application engineering knowledge Piab supports the ambitious Additive Manufacturing industry and has configured specific set-ups of its premium piFLOW®p vacuum conveyor for different pure metal and alloy types as well as different production settings, and can be used in filling the printer, sieve or hopper or to reclaim metal powder from the printer.

Filling the printer with metal powder

In this step virgin or reclaimed metal powder is transported from a sieve/metal barrel or hopper to the printer. Piab’s vacuum conveyors can pick-up powder directly from the barrel and feed the printer – this increases productivity as well as employee safety.

Sieve or hopper filling of metal powder

Feeding virgin or reclaimed metal powder to a sieve or hopper is usually done manually which is heavily dependent on the operator and exposes the employee to metals and heavy lifting. Moreover, it is hard to ensure that all metal powder is picked-up from the barrel/container which results in loss of valuable material. Piab’s piFLOW®p can effectively feed the sieve or hopper directly from the original manufacturer barrel/container which leads to automated process and improved productivity, reduced dependence on the operator and safer and a more ergonomic working environment. The vacuum conveyor can be integrated in portable sieving solutions due to their light weight allowing to use same vacuum conveyor and sieve solution with different printers.

Reclaiming metal powder from the printer

Metal powders are both expensive and hazardous so the proper reclaim from the printer is crucial. Piab’s piFLOW®p vacuum conveyors can transport metal powders from the printer to the sieve or a barrel via an enclosed system and not only increase productivity but also ensure employee safety.

Important considerations in metal powder conveying

The conveying of metal powders in Additive Manufacturing poses challenges, starting with the high bulk density. Metal powders can weigh up to eight kilograms per liter (kg / l), while powders in the pharmaceutical or food sector are generally between 0.8 and 1.2 kg / l. This requires significantly more powerful vacuum systems to keep the metal powder moving. At the same time, only relatively small quantities are needed for a production process, usually no more than 100 kilograms per hour - that is 12.5 l in volume conveyed.

Due to the high bulk density and the large filter in the system as well as the additionally required exhaust air filter to ensure employee safety and site protection, a correspondingly large-sized vacuum pump is required to achieve the necessary suction power. The production time in the 3D printing process is relatively long and the active conveying times are low. Thanks to the automatic shutdown of the vacuum pump at idle, the piFLOW®p vacuum conveyor is very energy-efficient, especially in comparison to mechanical pumps, which must continue to run at idle. Thus, the energy costs for the automated delivery and filling remain low. Unlike mechanical pumps, compressed air generated vacuum is not adding any heat to the 3D printing process.

The small footprint and low building height make Piab’s vacuum conveying system an attractive solution to be built in or integrated in an overall 3D printing offering or portable sieving solution. Moreover, the light weight allows to use same conveyor and sieve solution for multiple printers. The design in a conical shape of the piFLOW®p makes it particularly stiff and rigid, eliminating the risk of implosion.

As vacuum conveyors for the Additive Manufacturing industry need to cope with the most demanding circumstances easy cleaning ability, combined with the innate strength, makes stainless steel – of which the piFLOW®p is made – the material of choice for the industry.

Recommended vacuum conveyor configurations

To identify the most interesting conveying set-ups for the Additive Manufacturing industry Piab has run numerous tests with various typical Additive Manufacturing materials, among others with stainless steel and aluminium powder. The tests were based on assuming that the barrel or container holding the powder is stored at a different location from where the printing takes place. Hence, for quantities between 200 to 500 kilograms distances of up to 50 meters where achievable as were height difference of up to eight meters.

Based on internal tests and designs Piab recommends following configurations for the Additive Manufacturing industry of its vacuum conveyors:

- piFLOW®p 3 liter with a 200 pump, PLR02 filter and conveying line 32mm

- piFLOW®p 3 liter with a 400 pump, PLR04 filter and conveying line 32mm or 38mm

Depending on the equipment chosen, quantities between 600 and 1000 kg/h and above can easily be conveyed with the above-mentioned set-up over a distance of 10 meters and up to a height of 8 meters. Larger quantities can be conveyed with the above equipment over shorter distances, alternatively Piab’s experts can configure a customized solution to meet respective needs.

Additional accessories such as feed nozzles, and adapters as well as a module to fit the receiver are available – as are customized solutions for inert gas applications and compact style conveyors.

Piab offers conveying tests with customer’s specific metal powders in its different test labs around the world.