OVM Pro 3D

Next level vacuum management.

OVM Pro 3D is an advanced on-line application designed to optimize and streamline the configuration and simulation of vacuum systems from a DIY perspective. Utilizing state-of-the-art digital modelling and simulation, Piab offers you to design, test, and refine your solution in a virtual environment before physical implementation.

Explore the benefits of OVM Pro 3D

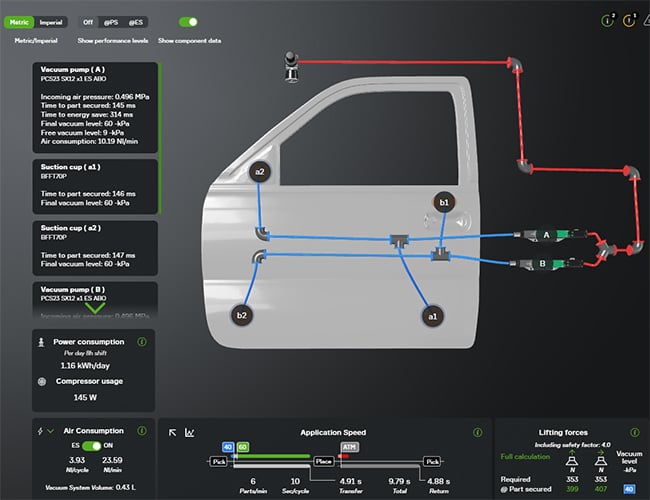

End result - Complete vacuum system

The design process takes off from your enterprise and process needs, offering a fully realisable and optimized vacuum system with the full integration of Piab’s extensive range of vacuum ejector pumps, suction cups, grippers, fittings and accessories. OVM Pro 3D offers you to design, test, and refine your solution in a virtual environment well before physical implementation.

Full customization, integration and compatibility

All your vacuum system designs can be tailormade to specific requirements. Seamless integration with a great variety of vacuum-driven components facilitates compatibility and ease of integration with an extensive range of vacuum systems. OVM Pro 3D ensures that all components are optimally configured for the application at hand.

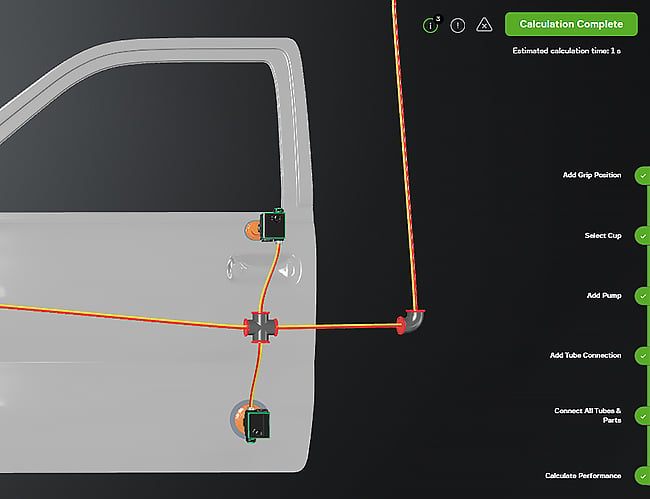

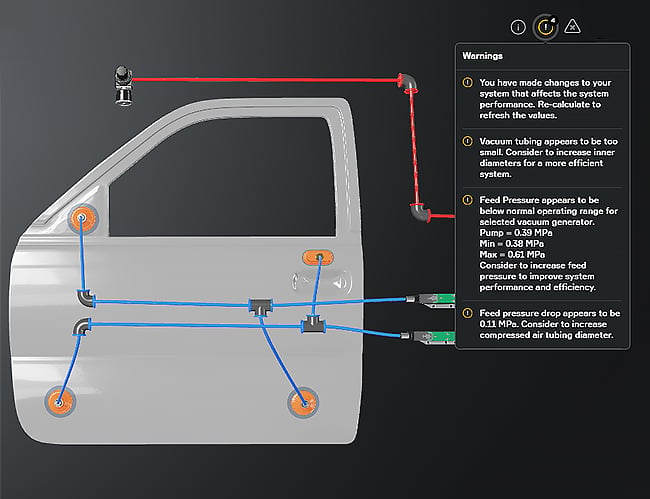

Error reduction and cost-effectiveness

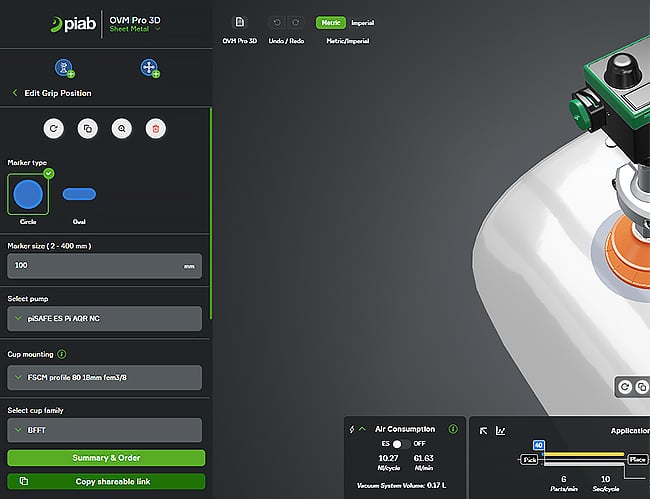

Pre-implementation, testing and visualization reduce the risk of errors during physical setup, leading to fewer operational issues. A visual checklist on the right side of the screen ensures that all steps are completed before attempting calculations, reducing the risk of errors. As everything is cost optimized before implementation, expenditures associated with trial and error, excessive use of materials, and inefficient configurations are saved.

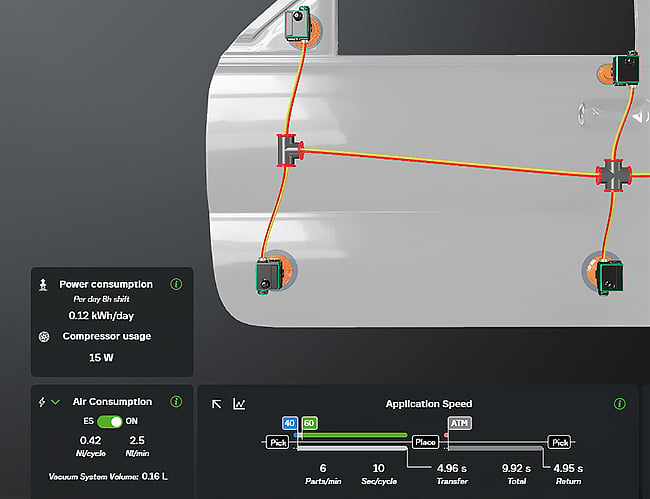

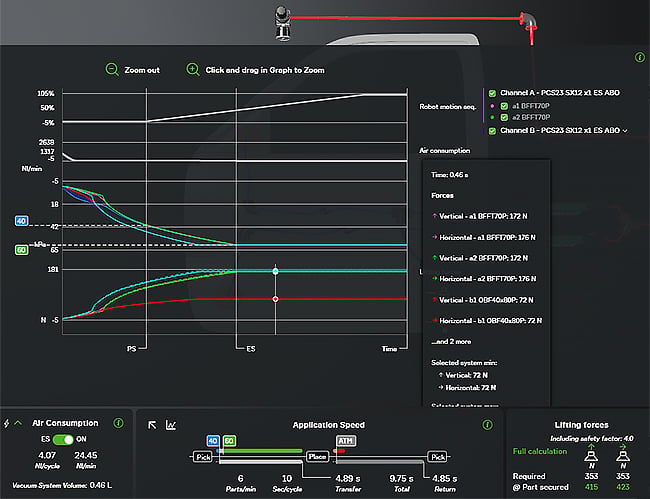

Visualized energy and power consumption

OVM Pro 3D uses visualization to help you understand and dimension the size and capacity of the compressor needed. The function displays estimated daily (8-hour shift) compressor electricity power consumption. It also visualizes the effects of energy-saving systems connected to compressed air consumption, measured in kW, and calculates pressure drops on both the pressure and vacuum sides, which is crucial for central vacuum systems.

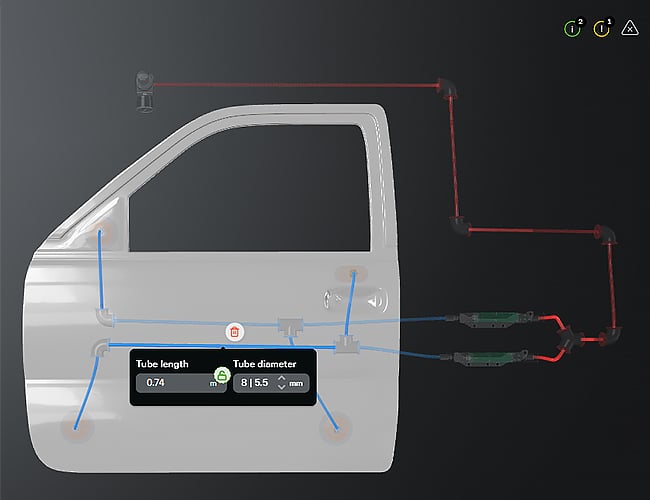

Effective component management

Direct editing of selected components and tube lengths is enabled within the system. All chosen components may be marked and “lit”, in groups or single, to enable moving/altering/exchanging throughout the whole process. Tubes set to specific lengths are marked with a "Z" and locked with a red padlock to maintain their length, even if components are moved.

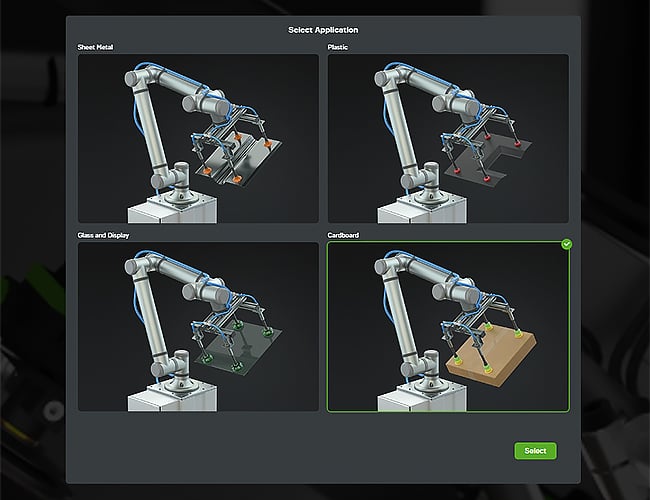

Useful applications

OVM Pro 3D provides preset application basics for materials like glass, sheet metal, plastic and carton. As an example, the carton feature includes a step-by-step wizard to define the cardboard used, mimicking real-life leakage parameters and vacuum level tests. Everything may then be fine-tuned to ensure precise dimensioning of the vacuum system as well as optimized energy consumption. This applies regardless of the material chosen.

Continuous performance data

All performance data is at all times positioned on the left side of the screen with a scroll function. Everything is displayed in an easy-to-use menu where any parameter may be altered. When hovering over the data, the specific product is zoomed in, and excluded components are dimmed for better clarity. Each component is indexed for easier connection to the graph information.

Warning symbols and safety questions

When in use, OVM Pro 3D provides detailed guidance from warning symbols. This includes actual pressure ranges for selected vacuum ejectors and optimal pressures, helping users make informed decisions. In addition, safety questions ensure that users are aware of the changes when switching between metric and imperial systems, and when changing applications.

Clear supportive graphs

OVM Pro 3D contains an enhanced graph feature for better observation. This includes a zoom function for detailed observation during crucial time frames, such as vacuum actuation and release phases. The total horizontal and vertical forces are displayed over the entire cycle of the vacuum system. This helps in analysing the lifting performance by showing data for each suction cup separately, and identifying the lowest and highest force values.

Why use OVM Pro 3D?

The OVM Pro 3D tool is a revolutionary application that enhances the efficiency and accuracy of vacuum system configurations before physical implementation.

Enhanced efficiency

OVM Pro 3D streamlines the vacuum system configuration process, making it quicker, easier, and in tune with the intended industrial process.

Customization

Tailor your vacuum system in a 3D environment to meet any requirement, ensuring an optimal configuration for a particular application.

Error reduction

Pre-implementation testing and visualization help reduce the risk of errors during the physical setup, leading to fewer operational issues in the future.

Cost savings

To optimize a system before implementation, saves costs associated with trial and error, use of materials, and inefficient configurations.

Energy optimization

Visualized compressor power usage and daily electricity consumption, supporting energy cost discussions and optimizations.

Specialized applications

Basic applications such as glass, sheet metal, plastics and carton included for precise dimensioning and testing.

Integration & compatibility

Designed to work seamlessly with any vacuum component or system, ensuring compatibility and ease of integration.

Detailed performance data

Provides detailed performance insights such as lifting forces and energy consumption, aiding in more informed decision-making.

Make the most of your design.

Thank you for requesting advice! We will be in touch shortly.