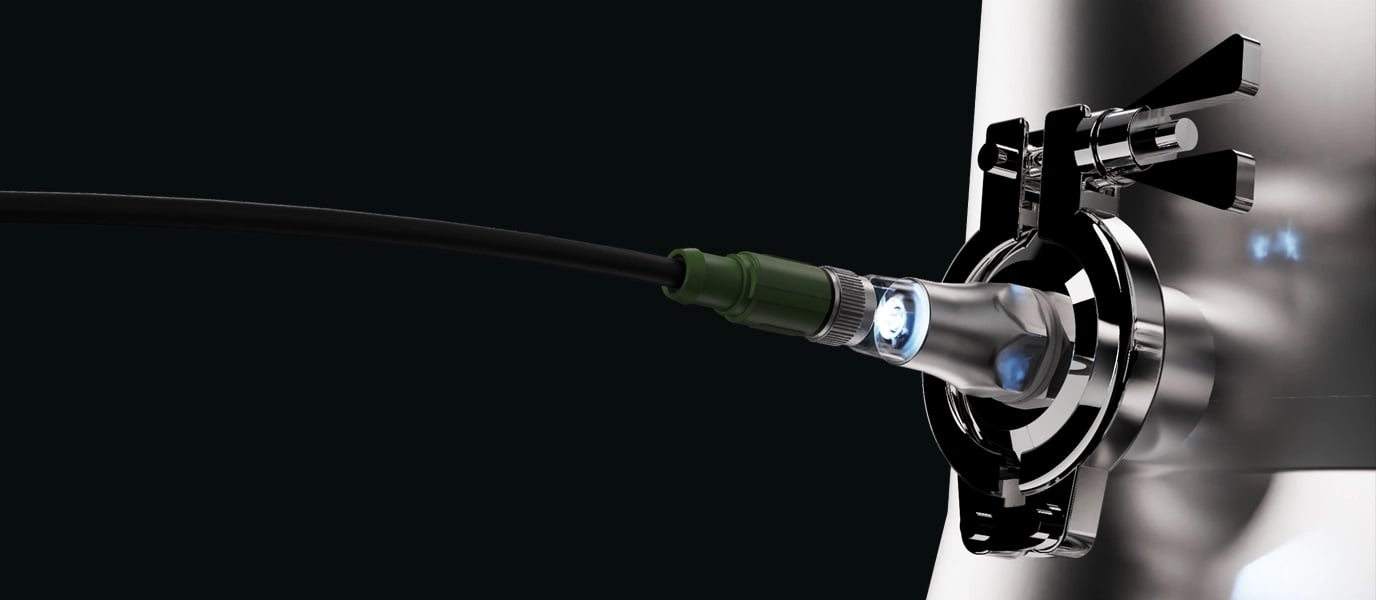

Confident conveying

piFLOW® Batch Volume Optimisation

While we upgrade our personal appliances regularly, we still tend to use legacy equipment and manually handle solid materials in our production lines. To reach productivity and sustainability goals, manufacturers need to tap into new technologies, while operators must on-board quickly.

Piab's new Batch Volume Optimisation series was created with the user in mind, they are designed to help continue evolving workplaces within the manufacturing sector.

Customizable, Versatile, and Scalable

No matter the distance, height, material, or capacity that will be conveyed, Piab has a solution for you.

Productive and sustainable

Even faster and more efficient conveying of bulk solids thanks to optimized batch cycles, avoiding unplanned downtime.

Reduces the possibility of human error

Operators intuitively learn how to set up and fine-tune the conveyor.

Allows Cut Down on Cleaning/Maintenance time

Thanks to the modular design, disassembly and reassembly takes only a few minutes.

Choose your product with Batch Volume Optimisation

A global team of application engineers facilitate the transition to piFLOW® Batch Volume Optimisation, providing the most suitable solution for any powder management challenge.

Are you curious how Batch Volume Optimisation could upgrade your processes?

Sign up for a 30-minute consultation and we will get back to you shortly.