- Success stories

- RO-BER operations pick up speed with Piab solutions

RO-BER operations pick up speed with Piab solutions

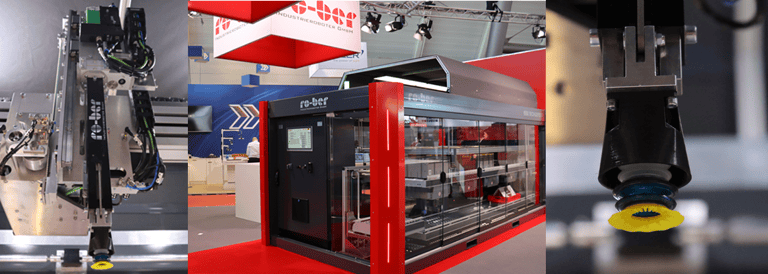

While creating a compact, piece-picking unit capable of handling various products and boxes at up to 1200 picks per hour, German system developer RO-BER found their solution in Piab's piCOMPACT®23 SMART pump and MX suction cups.

In the fast-paced world of intralogistics, precision, efficiency, and flexibility are essential. The collaboration between RO-BER Industrieroboter GmbH and Piab exemplifies how the partnership of two experts an revolutionize the industry. RO-BER, renowned for its high-performance area and line gantry robots, specializes in automating tasks like palletizing, depalletizing, picking, storing, and handling. To remain competitive and increase productivity advanced gripping technology is required to fulfil these complex processes successfully. This is the expertise where Piab excels.

The ambition was to create a compact, turnkey piece-picking cell capable of handling products of various shapes, sizes, weight and packaging types. The solution should ensure reliable and flexible gripping at high speeds of up to 1200 picks per hour. piCOMPACT®23 SMART and the #1 item picker MX cup of Piab can provide the solution RO-BER has been looking for.

Piab's multipurpose MX suction cup provides outstanding flexibility and reliability, making it perfect for handling diverse products. Its ability to grip various surfaces securely, even at low vacuum levels, makes it ideal for this application. piCOMPACT23® SMART is an intelligent compact air-driven multistage ejector, based on COAX® technology, offering integrated control and special functions, such as vacuum switch, on/off valve, energy saving features and more. The pump enables unparalleled control over the gripping process. This precision is critical for the efficiency and reliability of the system, especially in an industry reliant on fast and precise movements.

RO-BER's new robotic cell, a compact version of their area gantry robots, offers a large working area within a small footprint. Compared to other solutions, this cell can process two source containers and three target containers simultaneously. Fully pre-installed and tested at RO-BER's factory, this plug-and-play solution minimizes disruption during implementation at the customer's site, saving significant time during commissioning.

The system's flexibility is evident in its ability to handle various products in pick-and-drop or pick-and-place modes, catering for execution of tasks with single, recurring products or hundreds of different items. This adaptability, combined with Piab's advanced technology, enables RO-BER to provide customized solutions for diverse applications.

RO-BER's decision to partner with Piab was based on a history of successful collaborations and trust.

"We chose Piab due to the excellent collaboration even before the project began. It was a chain of successful results that brought Piab into close consideration as a partner for the cell, and so far, I can only say that we are very satisfied with the products.", states Alexander Lux, a designer at RO-BER Industrieroboter GmbH.

Local presence and swift responses of Piab experts, enable RO-BER to accelerate further system developments and optimizations.

This partnership between RO-BER and Piab demonstrates how innovative technologies and close collaboration can sustainably transform automation tasks. By merging RO-BER's automation expertise with Piab's advanced gripping technologies, efficiency and productivity are significantly enhanced, paving the way for new possibilities in intralogistics.

About RO-BER Industrieroboter GmbH

RO-BER is an innovative technology company with a strong market position. For over 40 years, RO-BER has been implementing complex robotic and material flow systems for international customers from various industries. The core competencies include automation solutions with gantry robots in the areas of (end-of-line) palletizing, depalletizing, picking, and buffering/storage; both in production environments and in the logistics chain.

For more information

Cindy Wenzel, Marketing Activation Specialist DACH

cindy.wenzel@piabgroup.com

Piab Vakuum GmbH, Otto-Hahn-Str. 14, 35510 Butzbach, Germany

www.piab.com