Piab blog

Industry 4.0 ready? Don’t forget about your manual sub-flows

Industry 4.0 has been on the agenda for quite some time now, but its realization is a far away from what fills our daily news feeds.

The complex road to simplicity

Our R&D department has been working with solutions for Industry 4.0. since 2017; I joined the team in 2020. It might sound controversial, but...

Choosing the right cobot gripper for cosmetics handling

For the cosmetics industry, placing products into packages is a particular challenge. Today this task is often fulfilled by an armada of workers, but with...

Ergonomic hazards in the Food industry and how to eliminate them

The food production line is a hazardous one. Therefore, it is extremely important to avoid...

Respiratory hazards in the Food industry and how to eliminate them

With allergies, asthma, and other conditions becoming more frequent, processors need to implement changes...

A great internal motivation driver

The X-Factor Interviews – Introducing the people behind the development of the MX Cup! Nicklas Holmgren – Content Creation Manager, Marketing Department – 5 years with Piab.

We do not copy others, we lead

The X-Factor Interviews – Introducing the people behind the development of the MX Cup! Lennart Ryberg – Global Product Manager, Vacuum Automation Division – 2.5 years with Piab.

Mapping the gaps of customer needs

The X-Factor Interviews – Introducing the people behind the development of the MX Cup! Johnny Skagersjö – Senior Application Engineer in Automation div. and part of the System Engineering & Research team, with Piab since 2004

“Lagom” – not the best for something but just right for anything

The X-Factor Series – Introducing the people behind the development of the MX Suction Cup! Gustaf Wigren – Director Product Technology, Conceptual System Design, Research & Development (R&D), Automation Division – 13 years with Piab

The thinner the lip the better the grip

The X-Factor Series – Introducing the people behind the development of the MX Suction Cup Jonas Herrström – Senior Design Engineer, Conceptual System Design, Research & Development, Automation Division – 8 years with Piab

New blog post: A gripping story

All stories have a beginning. The story of piSOFTGRIP® started with passion.

Help for strawberry shortcake lovers

With Piab's combination of conveying, gripping and lifting tools, strawberry shortcakes can be baked quickly and safely packed for transport.

It’s down to collaboration

Cobots enable greater collaboration between humans and machines. In order to do so, cobots need cleverly designed end-of-arm tools (EOATs).

Is it safe or even possible to transport dry materials in high heels?

Safety should always come first when you work in manufacturing. Does that mean that you should stay away from manufacturing industries if you love wearing high heels?

Do you really need to be ready for Industry 4.0 or not?

Ready or not - we have come up with a solution that works for everyone.

Another product family for the automotive industry

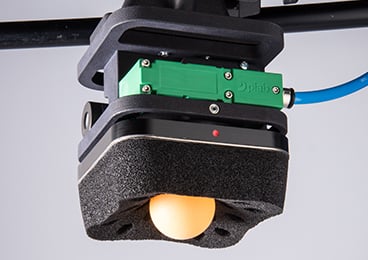

Piab maximizes productivity in the automotive industry with flexible suction cup mount.

One plus one makes three!

Two years after acquiring Kenos®, Piab develops the perfect small business all-rounder – Kenos® KCS.

Yet another contribution to Industry 4.0

It is fascinating when you realize that you have developed the right product and the right functionality for the market and customer, even before all of the interest around Industry 4.0 came to light.