Nutraceuticals conveying

Nutraceuticals or food supplements are produced in an exciting industry with various challenges. Products can vary from tablets and capsules to powdered products and even gummies. Producers often have to apply food-grade equipment on their production lines but sometimes even follow cGMP protocols. No matter the case, typically used solid materials can easily be handled by the right Piab vacuum conveyor.

Nutraceuticals Manufacturing Equipment by Piab

Here's how Piab’s conveying systems ensure a smooth nutraceutical or food supplement production.

Picking up solid materials from barrel, IBC, bag, or big bag

Producing nutraceuticals starts with introducing ingredients to the process with the right method. Piab offers a wide range of accessories, like feed wands, feed nozzles to pick up materials from drums or IBCs, a bag dump station for emptying bags, and big bag unloading options with feed adapters to regulate the air/material ratio.

Transport nutraceuticals to and from blender and mixing units, sieves, V-blenders, and fluid bed drying discharge

Mixing is a highly complex operation, and it is crucial to have the right mixing and transporting solution from the start. This helps ensure complete control over the numerous factors affecting mixing efficiency and end-product quality. Piab conveying systems play a crucial role in the efficient operation of mixing and blending processes in food supplement manufacturing, including the special case of feeding V-blenders. Further on, they are used in the process to feed sieves or to discharge fluid bed dryers among others.

Supplement material conveying to capsule filler

After primary processing, like mixing and blending, the supplement material mix, whether it's powder or granules, also needs to be conveyed to the filling machines. Piab conveyors transport the supplement material to the capsule filling stations, dispensing it into the capsules.

Empty capsules must also be transported from their storage containers to the filling stations. Conveyors are used to move the empty capsules in an orderly manner to ensure a continuous supply for the filling machines.

Feed the tablet press

Productivity and workspace ergonomics can be greatly enhanced with Piab vacuum conveying. Feeding the tablet press becomes easy, and the ready-made tablets can be gently moved toward the tablet coater or to the packaging line. Segregation/separation of the raw materials in mixes and chipping of tablets are avoided with the appropriate Piab vacuum conveyor, which leads to increased efficiency and productivity.

Fill nutraceutical sachets

The Austrian Kora Füll GmbH uses piFLOW®p conveyors to fill superfoods efficiently into stick packs. Their decision was based on Piab's great local support, easy cleaning and maintenance, and enhanced occupational safety and comfort. In this example, their Piab vacuum conveyor runs with a 500kg/h capacity and conveys powdered materials to 10 meters distance.

It was important to us that the conveyor can be cleaned not only in the shortest possible time but also thoroughly so that no residues of the previous produce contaminate the next - especially in the case of allergens, which would be an absolute no-go.

Packaging of supplements and nutraceuticals

After the capsules are filled and sealed and/or the tablets are pressed and coated, they are typically packaged into bottles, blister packs, or other containers. Piab conveyor systems are used to transport the capsules or tablets to packaging, labeling, and capping stations for final processing before distribution.

A solution for automation with many applications

The nutraceutical industry is a world between food and pharmaceutical industries and can cover various practices from functional food or food supplement production to sterile pharmaceutical production. This variety implies a diversity of requirements for manufacturing hardware, all while preserving product integrity is a standard requirement. Most conveying equipment has to be food-grade only, but in some cases, more rigorous rules apply, especially if the conveyed material poses a health risk to the operators.

piFLOW® for the nutraceuticals industry

Piab offers a wide range of vacuum conveyors for all these needs, including food-grade and antistatic ones with ATEX dust or ATEX gas certifications. To convey powders and granules, one of the piFLOW®p or piFLOW®c models is recommended, depending on the needed capacity, the material characteristics, and even the level of manual intervention from the operator at setup and ongoing use.

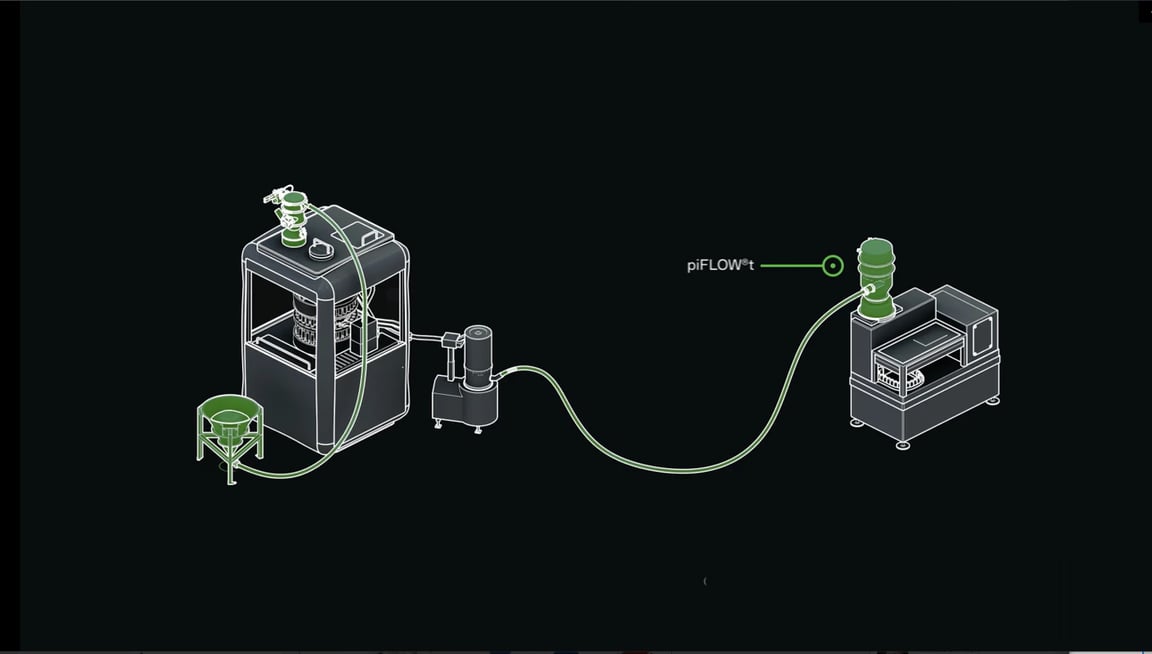

piFLOW®p is available with four different automation levels, ranging from the standard product to the completely automated Auto-tuning. To transfer tablets or other more vulnerable materials, we recommend using piFLOW®t, equipped with the piGENTLE® technology to avoid chipping the tablets during transfer.

Vacuum conveyors can be applied throughout multiple stages of the production line, including the charging and discharging of tablet presses, capsule filling machines, mixing and blending units, roller compactors, and auger fillers all the way to packaging. A common misconception about vacuum conveying is that it necessarily damages the product or leads to product separation in powder mixes. With the appropriate settings and the right sizing, Piab conveyors overcome these challenges, so you don't need to worry about variations in product formulation. The small footprint also allows for a flexible layout.

Why convey with Piab?

Fulfills the requirements

All Piab vacuum conveyors fulfill various requirements applicable across the nutraceutical industry. Our application engineers can help choose the right equipment to use.

Ensures productivity

The material supply is not dependent on the operator's physical capabilities and provides for a continuous process. Avoiding manual handling also contributes to better occupational health and safety, all while increasing system uptime.

Avoids product segregation

The powdered products stay consistent in the conveying process. Tablets and small particles, on the other hand, will not be damaged through the gentle conveying process.

Small footprint

Piab vacuum conveyors have a compact, modular design that allows them to be easily retrofitted, maintained, and cleaned. They also fit constrained spaces when they have to be mounted above bigger equipment, such as packaging machines.

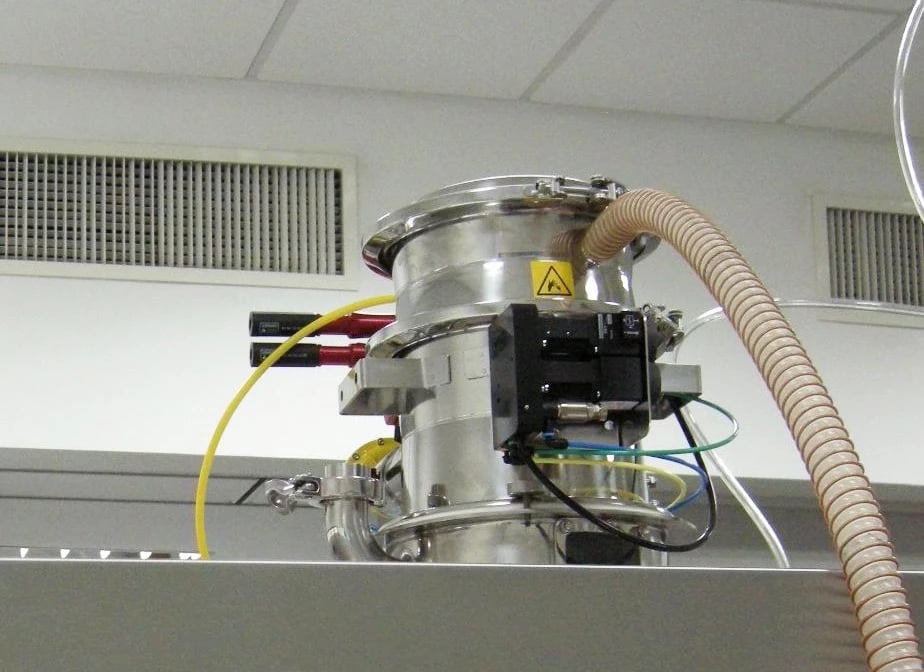

piFLOW®p in real-life setting

piFLOW®p under maintenance

Operator inspects piFLOW®p

piFLOW®p feeding a sachet filling machine

piFLOW®p

FAQ

Do you have appropriate certifications even if we apply processes usually present in the pharmaceutical industry?

Yes. Paib vacuum conveyors can be used in cGMP environments in the pharmaceutical industry. The right conveyor to choose depends on what rules you need to comply with, but there is a solution to a wide range of needs. Equipment with certifications for FDA, ATEX, CE, European food regulations, and QC is available.We have a high-end product where the precise formulation of the ingredients is crucial.

Are these solutions applicable even for delicate product mixes?

Yes, with the right settings and sizing, Piab conveyors avoid the risk of product segregation/separation.I learned that pneumatic conveying techniques often have high noise levels.

What applies to your products?

Noise levels allow a low tone conversation beside the conveyor, which makes these solutions of the lowest possible noise level.

How to clean a vacuum conveyor?

Disassembling the conveyor usually takes a few minutes, thanks to the modular design. It is a toolless process and once the conveyor is disassembled, the filters can be changed and the whole conveyor body can be cleaned out. Cleaning is usually necessary in case of frequent product changes. There is detailed advice in the product manuals on the topic.

Is there a warranty on the products?

Yes, there is a 5-year warranty on the main parts of all Piab vacuum conveyors. There are also application engineers available in case you need help with startup, maintenance, operator onboarding, or follow-up.

Get help choosing your ideal conveying equipment!

Find out what applies to your raw materials and products! Fill in the form to get free, personal advice from our engineers as well as comparisons with other technologies to find the best solution for your needs.