Pet Food Conveyors

Vacuum conveyors are a vital component in overcoming the challenges of pet food manufacturing, offering solutions that improve product handling, enhance workplace safety, and support efficient, flexible production while respecting FDA pet food handling guidelines.

The pet food manufacturers: Serving a growing market

In a market where customers increasingly seek pet products that mirror human food in terms of nutritional content, production quality, and variety, pet food manufacturers are innovating the pet food industry by introducing more or new products.

The pet food industry is growing both in sales and production and is expected to reach 290 Billion USD in 2029. The major factors driving this growth besides the demand for premium food include rising pet adoption and more acceptance of pets across the globe.

Piab’s pet food conveyor and vacuum technology offer manufacturers cutting-edge solutions that set new industry standards.

Pet food processing: Different products, different requirements

Pet food processing involves a diverse range of materials tailored to the specific needs of various animals, including cats, dogs, rabbits, fish, and other pets. The primary materials to transport in pet food are typically pellets (kibble) or different types of animal feed and their ingredients and nutritional additives.

The foundation of pet food usually consists of grain powders, which are then blended with meat, bone powder, or fish powder to enhance flavor. Common raw materials include flour, rice, bone powder, and fish powder. Beyond the basic components, other ingredients like nuts, seeds and bone biscuits are often used to create specialized pet food products. Each type of pet food requires careful consideration of the specific ingredients and processing techniques to ensure the final product meets the needs of each animal.

To transport all the dusty ingredients and avoid contamination of products, an enclosed vacuum conveying system can help. With our Piab solutions manufacturers can upgrade their capacities, increase efficiency and ensure safe and ergonomic working conditions.

Vacuum conveying: Pet food conveyors for dry pet food and ingredients

Piab's vacuum conveyors are designed to meet the demands of low building height, compact footprint, ease of cleaning, and low noise levels. Their enclosed and contained system effectively minimizes dust dispersion during the transport of ingredients or products.

Applications vary based on the type of pet food—wet or dry. In wet pet food production, the system conveying dry ingredients has to be easy to clean, especially when working with oily ingredients. Our pet food conveyors are also well-suited for manufacturers who frequently change recipes.

For dry pet food production, where processing is typically done at high volumes (tons per hour), our conveyor systems are more applicable in smaller-scale operations. We focus on moving smaller batches, such as micro-batching, handling micro-ingredients (a few kilograms of materials), or transporting additives.

Piab conveyors handle a wide range of materials, including

Powders: APIs, excipients, and milk powder.

Granules: Formulations ready for tablet pressing or encapsulation.

Sensitive Materials: Freeze-dried powders requiring gentle handling.

Stringent regulations are easy to meet with Piab conveyors. They are also able to handle sensitive materials with gentle care. In pet pharma, maintaining the integrity and efficacy of active ingredients is essential as well as precision in blending and mixing. Just like human medicine production, pet drugs also need to be produced while maintaining formula consistency to reach exact compositions and dosages.

Choose the conveying equipment which is not damaging your ingredients and products all while being compliant with regulations in the pet medicine industry.

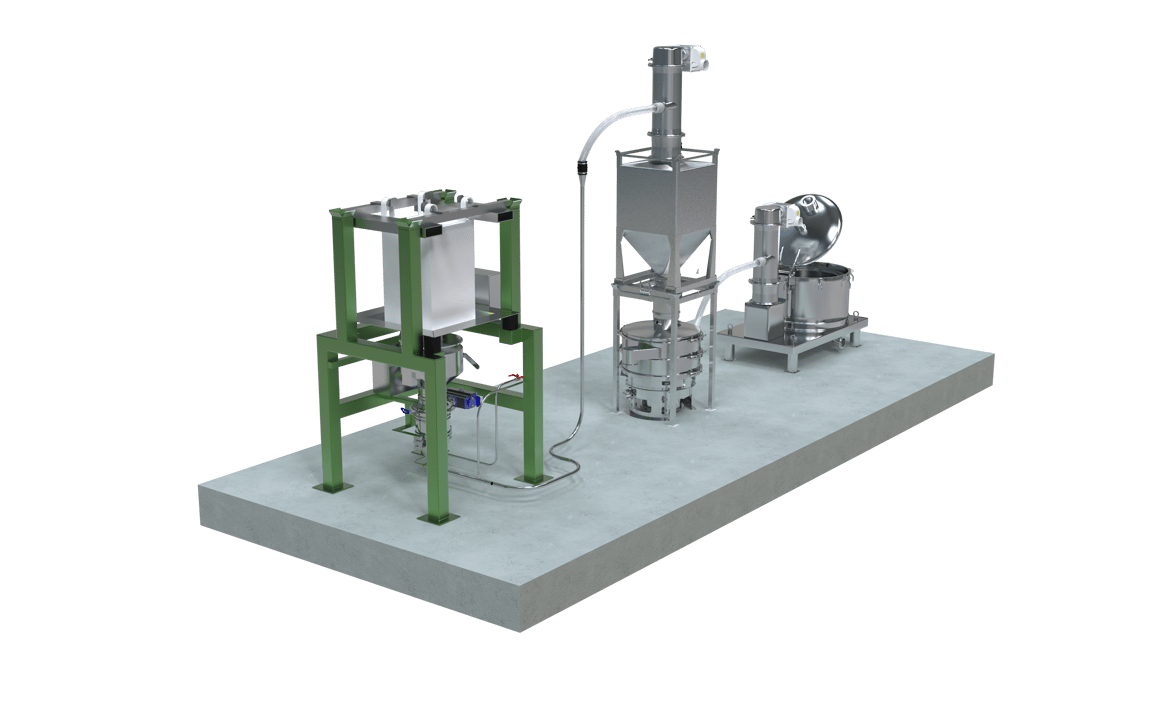

Automation of anode material manufacturing process

Piab vacuum conveyors can easily be used in the process of manufacturing anode materials as well. In this example, the material is conveyed from a bulk bag with a vacuum conveyor, through a vibrating sieve, then into a grinder. Fine graphite powders can be distributed to spheroidization and ultra-fine pulverization process steps as well – even when material integrity is inspected to the micrometers.

Vacuum solutions for battery production: Compatible with all process steps

From handling large volumes of solids (up to 14 tons/h or 30 000 lbs/h) at the process start to managing smaller, purity-critical volumes at the end, Piab offers solutions for every stage of the battery production processes. Transition pieces connecting the conveyor and the discharged/receiving equipment are available based on the application at hand.

Conveying micro-additives for pet and farm animal food

In Poland, Conberg has implemented Piab's vacuum conveyors to address micro-additive handling in animal food production. Positioned eight meters above ground, the system ensures precise, dust-free transfer of ingredients like enzymes and vitamins, enhancing both efficiency and ergonomics in the process.

Benefits of conveying ingredients and pet food products with Piab

Piab's vacuum conveying systems offer a versatile and efficient solution to several challenges in the pet food manufacturing process, ensuring smoother operations and higher product quality.

Move fragile kibbles

Handling fragile kibbles requires a gentle yet effective transportation method to prevent breakage. Vacuum conveyors provide a smooth, enclosed system that minimizes the risk of damaging delicate kibbles.

Transport micro ingredients

Precision is key when dealing with micro additives and micro ingredients, which are often added in small quantities. Vacuum conveyors are ideal for accurately handling these materials, ensuring consistent and precise dosing throughout the production process.

Reduce manual work

Our pet food conveyors significantly reduce manual handling of materials, which helps to minimize ergonomic risks associated with repetitive lifting, carrying, and pouring. By automating these tasks, pet food manufacturers can create a safer work environment and enhance overall efficiency.

Space-saving solution

With their compact design, Piab vacuum conveyors are perfect for facilities with limited floor space and low building heights. They can be easily integrated into existing production lines, optimizing the use of available space without compromising performance.

Easy cleaning

Our pet food conveyors are designed for easy disassembly and cleaning, allowing quick changeovers between batches while maintaining high hygiene standards. This ensures that cross-contamination is avoided, and the integrity of each recipe is preserved.

Low noise level

Low noise levels are an added benefit, contributing to a quieter and more comfortable working environment.

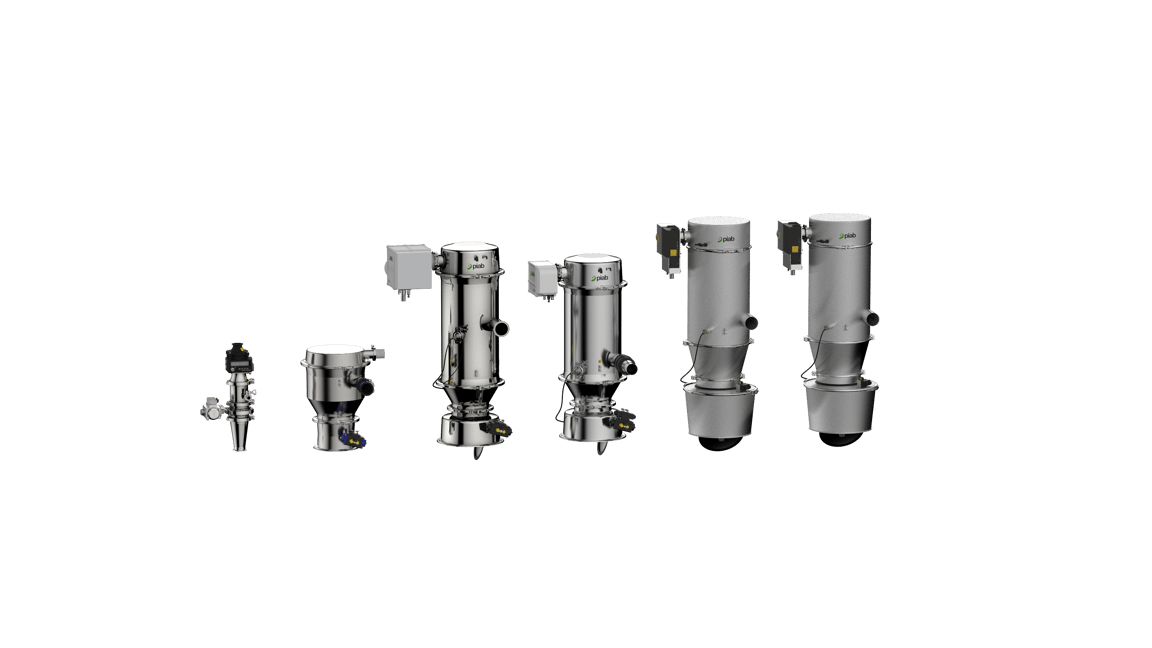

In terms of vacuum conveying there are several options.

The piFLOW®t ensures gentle conveying of final dry food product e.g. for packaging into bags preventing breakage of the product.

The piFLOW®p with auto-tuning option is especially useful when many different powders or granules are conveyed that need to be changed regularly as this system does not require particularly skilled operators and performs the changeover in 10 minutes rather than an hour, ensuring full conveyor capacity usage with each cycle.

The piFLOWW®fc serves as the best heavy-duty option when FDA guidelines are in place.

Vacuum conveying systems help to provide the right amount of ingredients or final products to the next processing or packaging step. Thanks to the closed system it also provides a dust free environment and protects the product from contamination. Product consistency and high quality is achieved through reliable transferring of raw materials and products throughout the process.

Being a crucial part of the batching system, vacuum conveying in the pet food industry increases the efficiency of batching processes by freeing up operator time as they need to spend less for material provision to the individual process steps, making these tasks also more ergonomic. Depending on the level of automation chosen the conveyor can work nearly operator-independent and the conveyor capacity is used to its maximum in every cycle.

Manufacturing pet food with the highest level of automation involves several key steps and technologies to ensure efficiency, precision, and quality.

Use Piab’s vacuum conveyors to ensure precise dosing of micro-additives, and bulk handling systems for ingredient handling and preparation. Convey powders to mixing and blending equipment, extruders, cooking, and coating process steps with vacuum, and use gentle vacuum conveying to feed the packaging machine with kibbles.

The main steps in pet food manufacturing include ingredient handling, mixing, extrusion, drying, and packaging. Piab's vacuum conveyors play a crucial role in almost all phases, ensuring precise and efficient transport of raw materials, micro-additives, and kibbles and other products throughout the production line.

Would you like to consult with an engineer?

Our team of application engineers and partners is ready to assist you in selecting the perfect vacuum conveying solution for your pet food production needs. Fill out the form if you would like to get personal support.