Logistics & Warehousing Automation Solutions

Piab’s comprehensive range of electric and vacuum-driven solutions for the Logistics & Warehousing sector has been developed to ensure that operations are efficient, reliable, and capable of meeting the high demands of modern product handling.

Piab's energy-efficient electric and vacuum-driven solutions reduce operational costs and environmental impact, aligning with sustainable logistics practices of all major industrial sectors.

Piab's consistent performance is characterized by the dependable operation of our electric and vacuum-driven handling solutions, which maximize throughput across various logistics and warehousing applications.

Piab's products offer endless possibilities through their modular design and adaptability, allowing for easy configuration and customization to meet specific application needs across all industrial sectors.

Automating every process step in your Logistics & Warehousing

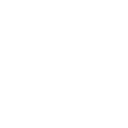

Automate your unloading process with smart logistics solutions

Piab offers advanced vacuum technology to automate the truck unloading process. Our solutions include vacuum pumps and gripping tools with either suction cups or foam, to enhance efficiency, safety, and true ergonomics. Piab enables quick, secure material handling with minimized risk of human injury or damage to handled products. Our smart logistics systems comply with all safety standards and regulations, including CE marking, which ensures that the equipment meets essential health and safety requirements.

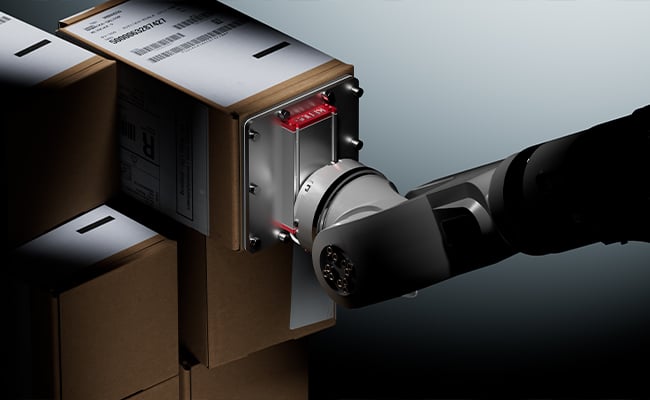

De-palletize with precision

By using advanced vacuum technology and modular components combined in sophisticated warehousing solutions, Piab drives the accurate, efficient, and safe lifting of products and boxes from pallets, ensuring flexible, cost-effective automation and reducing manual handling. Our versatile vacuum pumps, grippers, and high-performing suction cups or foam, are all examples of tools contributing to our superior de-palletizing systems.

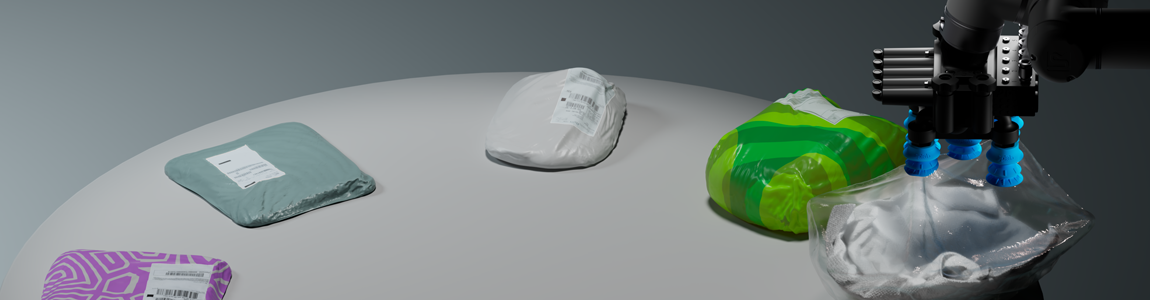

Grip and sort with care

The clever vacuum driven pumps and grippers coupled with a generous assortment of standard and modular suction cups with smart accessories, offer peerless handling of industrial products. Piab ensures precise gripping and sorting through both electric and vacuum-driven technology and customizable components. All our cobot-assisted logistics and warehouse solutions come with plug & play software and unique energy-saving features.

Ask us anything.

Receive free consultation and advice from our automation specialists on how to reinforce your process.

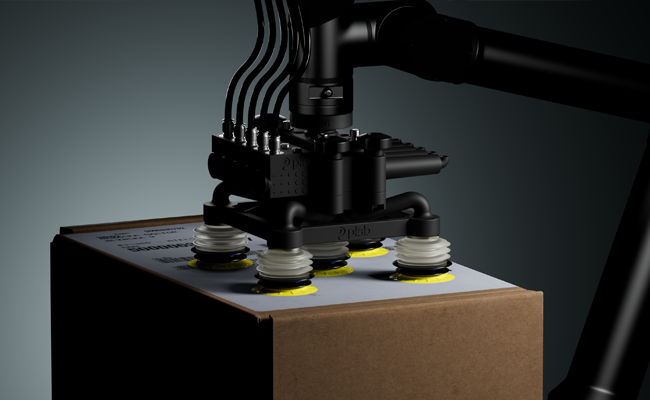

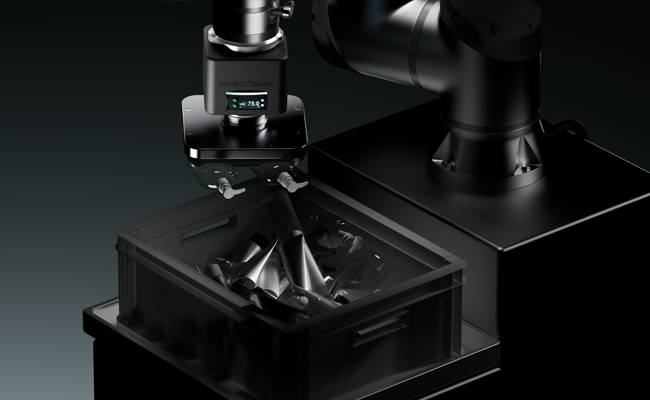

Perfect your bin-picking

Piab's advanced lightweight vacuum grippers elevate cobot bin-picking to new heights. Our innovative warehousing solutions accurately identify and securely grip any item, regardless of size, weight, surface structure, or height, without the need for tool changes. By improving picking speed and ensuring reliable handling, Piab perfects the bin-picking process, making smart logistics and warehouse operations more efficient than ever.

Handle all totes efficiently with warehouse automation solutions

Piab's compact and lightweight vacuum pumps, combined with versatile grippers and specialized suction cups, ensure efficient handling of totes, regardless of type or material. Leveraging our advanced COAX® technology, Piab guarantees secure and precise high-speed gripping, lifting, and moving within any automated warehouse operation. Our goals are enhancing efficiency, reducing manual effort, and boosting throughput.

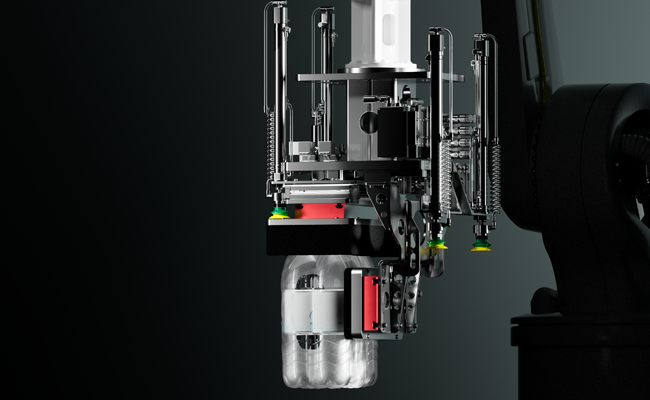

Maximize cobot capabilities with electrical pumps

Piab's energy-efficient electrical pump technology allows for higher flexibility within any industrial sector. As no compressed-air infrastructure is needed, cobots may be placed independently in the warehouse facility, offering expanded movement due to less tubing and cables. As our worker-friendly grippers are also lightweight, they allow for maximized payloads of the cobot arms. As a whole, this boosts productivity and warehouse energy efficiency throughout the facility.

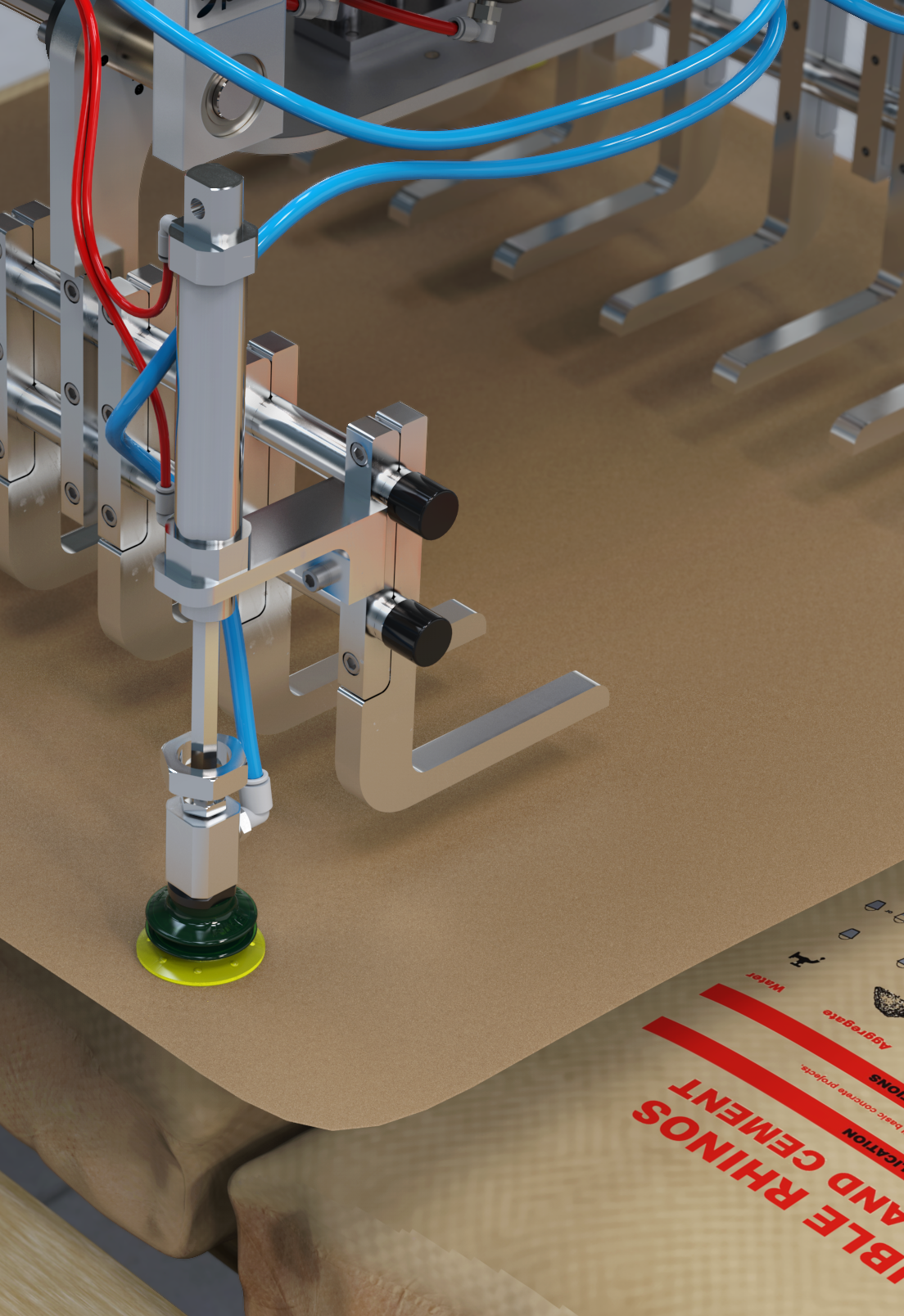

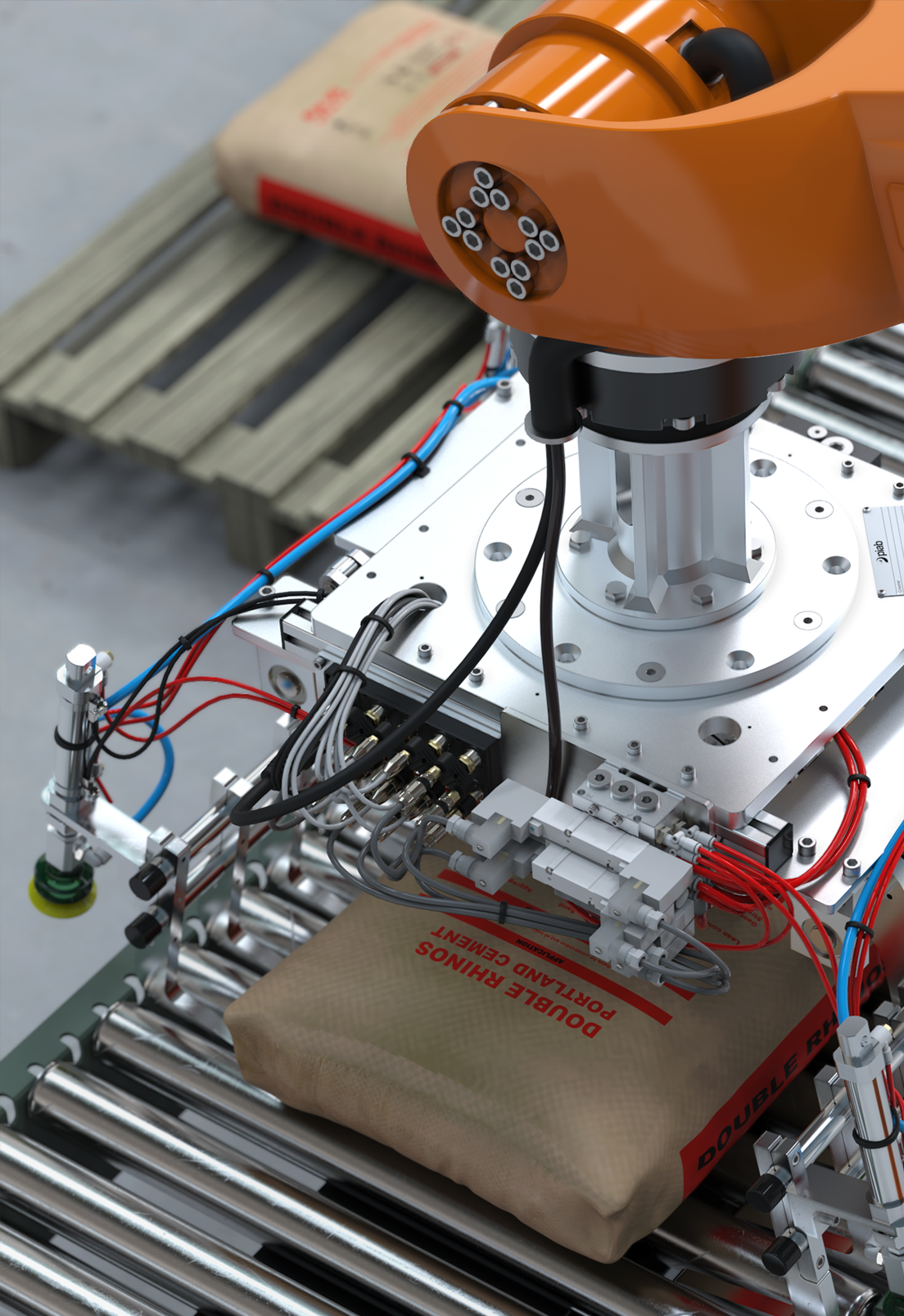

Palletize it all with one gripper

Flexibility is key when it comes to palletizing. With both standard and custom designs, Piab enables a company to palletize diverse items with one single gripper tool. Our versatile instruments can handle any shape, size, surface quality or material which ensure reliable, streamlined palletizing and slipsheet handling without manual labour. Real logistics efficiency without the risk of human injury or damaged products while keeping energy costs low.

Boost your cobot palletizing

Piab’s top-performance cobot palletizing expertise shines through our successful portfolio of cobot grippers and modular suction cups, delivering precise and adaptable warehouse solutions across various industrial sectors. Each product is meticulously designed for compactness and energy efficiency, enhancing speed, accuracy, and flexibility to maximize throughput in automated warehouse operations. User-friendly plug-and-play setups and easy maintenance ensure quick installation and significantly reduce downtime, making our solutions both efficient and reliable.

Explore more warehouse automation solutions

Piab supports several additional logistics and warehousing applications with its extensive product portfolio of vacuum pumps, grippers, suctions cups, optional features as well as suitable accessories:

Solutions for micro fulfilment

Solutions for micro fulfilment

Slip sheet handling

Cans and jars handling

Handling of heavy objects

FAQ: Piab's Logistics and Warehousing Solutions

How can Piab's solutions improve efficiency in logistics and warehousing?

Piab's solutions automate material handling processes, reducing manual labor and increasing throughput. This leads to faster loading and unloading times, streamlined operations, and enhanced productivity.

Can Piab's solutions handle a variety of materials and products?

Yes, Piab's solutions are highly versatile and can handle a wide range of products, regardless of size, weight or surface structure. Customizable components like suction cups and vacuum gripping systems ensure secure handling of different items.

Are increased efficiency and speed part of the Piab offering for warehouse operations?

Yes, Piab's advanced automation technologies and equipment are designed to streamline and optimize various aspects of logistics operations, which directly contribute to improved order processing and on-time delivery performance.

Is it possible to save energy while you automate your warehouse?

Yes, Piab provides tools for automation that lead to significant energy savings and reduced environmental footprint through optimized solutions, energy saving innovations and systems for local energy management - for compressed air as well as electricity.

How do I get started with Piab's logistics and warehousing solutions?

To get started, you can contact Piab directly or reach out to your local Piab distributor. Piab's experts can provide detailed information, product recommendations, and support to help you implement the best solutions for your logistics and warehousing operations.

Can Piab's solutions be customized to meet specific needs?

Yes, Piab offers customizable solutions to meet specific logistics and warehousing needs. For example, piGRIP® modular suction cups can be tailored to suit different shapes, sizes, and materials, ensuring a secure grip during handling.

How do Piab's vacuum generators enhance logistics operations?

Piab's vacuum generators, such as the piCOMPACT® series, provide high-efficiency vacuum generation with integrated controls. They are ideal for automated warehouse systems, ensuring quick and reliable handling of materials.

Are Piab's solutions compliant with industry standards?

Yes, all Piab's products and solutions comply with various industry standards and regulations.

Evolve your logistics and warehousing business with us

Piab is one of the preferred choices for companies looking to enhance their logistics and warehousing capabilities through advanced, reliable, and efficient automation solutions:

- Substantial energy savings. By utilizing vacuum-based products and components, Piab can offer solutions with unparallelled energy efficiency, thereby complying with corporate policies and contributing to global environmental goals.

- Reliability. Piab products are developed and produced with durability and reliability in mind, enabling continuous operation and minimizing downtime in critical logistics and warehousing operations.

- Safety. Safety is paramount in logistics. Piab's end-of-arm-tools (EOAT) and other sophisticated solutions are designed to ensure safe operations, protecting both goods and human operators as well as the environment where the operation is set up.

- Scalability. As businesses grow and their needs evolve, Piab's solutions can scale to meet increased demands without compromising performance, making us a long-term partner in logistics efficiency.

- Maximize flexibility. Multi-purpose all-in-one-grippers for warehouse operations driven by intelligent pumps with easy-to-maintain set-ups, help handling a wide spread of items like bottle packs in foil or carton, cans and jars, slip sheets, and ultimately even pallets.

Not sure what you need?

Our Logistics & Warehousing team is ready to assist you.