Metal Additive Manufacturing

Metal additive manufacturing is a quickly emerging industry with strong technology focus to continue improving its productivity and efficiency while maintaining high quality and adhering to health and safety standards. Raw materials used are primarily metal powders like titanium, nickel, stainless steel, cobalt, iron, tungsten carbide, all with their individual challenges.

What is additive manufacturing?

Metal additive manufacturing, also known as metal 3D printing, is an advanced manufacturing technique that involves building three-dimensional objects layer by layer using metal powders.This process is quite different from traditional subtractive manufacturing methods, where the material is removed from a solid block to create the final product. In metal additive manufacturing, the object is created by adding the material layer by layer until the desired shape is achieved.

How does 3D printing with metal work?

The metal 3D printer selectively fuses or sinters the metal powder layer by layer, following the sliced design. Various techniques are used for metal additive manufacturing, such as selective laser melting (SLM), electron beam melting (EBM), or binder jetting where a high-energy source is used to selectively melt or fuse the metal powder.

Our applications for metal additive manufacturing

Operators usually feed the printers, the sieves, or hoppers manually from small bottles. Therefore, the process relies heavily on manual labor and exposes the employee to hazardous metal powder dust and heavy lifting. Automating the process enables higher productivity, as well as safety and an ergonomic working environment for the employees.

In metal additive manufacturing, Piab vacuum conveyors can be used to enable automation of the whole process, but particularly used in the following process steps.

These solutions result in a higher level of productivity, avoid product scrap, and establish an ergonomic working environment:

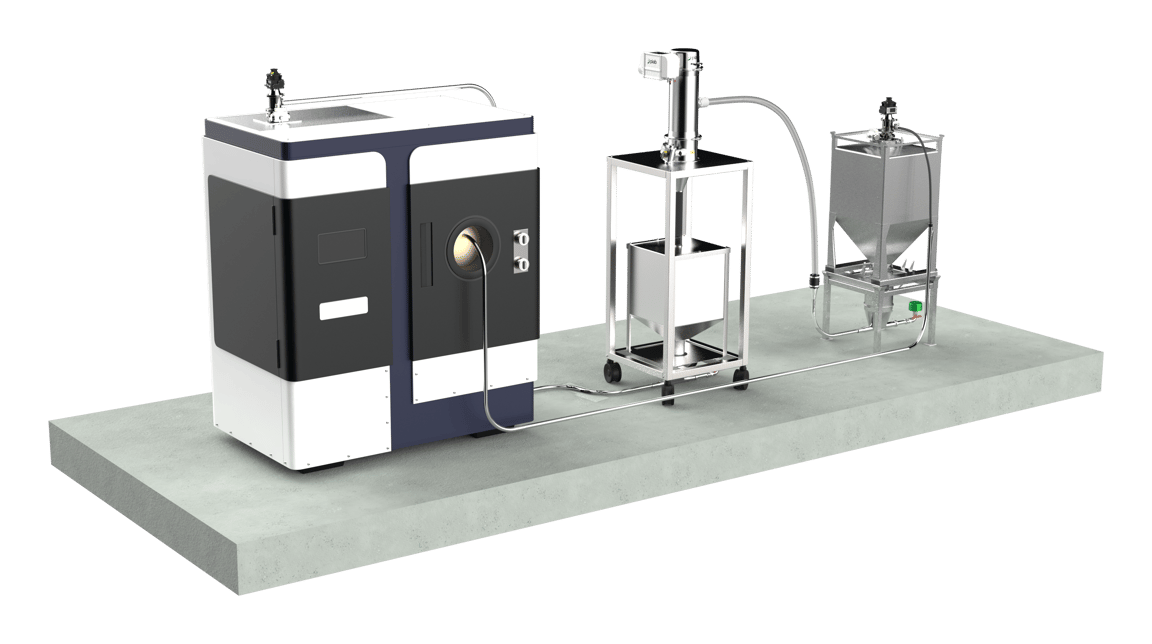

Filling the 3D printer with metal powder

Piab vacuum conveyors pick up the virgin or recovered metal powder directly from a sieve/metal drum or hopper and feed the 3D printer. The removal can also be done directly from the overflow container.

Filling a sieve or hopper with metal powder

Piab vacuum conveyors can feed the sieve or hopper directly from the original manufacturer's drum or vat when pre-sieving is required or recover metal powder from the 3D printer's overflow vessel. Our conveyors for metal additive manufacturing can be integrated into portable sieving solutions due to their ease of assembly and light weight, allowing the same conveying and sieving solution already used for printers.

Recovering metal powder from the printer

Metal powders are both expensive and hazardous, so proper powder recovery from the printer is critical. Piab's piFLOW® vacuum conveyors can transport metal powder from the printer to the original manufacturer's sieve or drum/container via a closed system to increase productivity and ensure the workers’ safety. It is possible to recover metal powder from the overflow hopper and build the plate directly from the printer or by using a Piab feed pipe.

piFLOW® by Piab: Our conveying solutions for metal additive manufacturing

With our extensive experience in material handling, Piab's vacuum conveyors have long been an efficient solution for handling powders. Here is what our Piab premium conveyors offer:

- a stainless steel (ASTM 316L) housing

- Piab's highly efficient COAX® vacuum technology

- ATEX dust and gas certification

- built-in automatic filter cleaning

- powder handling up to ca. 8 kg/liter [500 lbs./ft3] bulk density and an impressive throughput

- minimal footprint

Piab provides the greatest flexibility by working with various additive manufacturing technologies, such as Powder Bed Fusion and Binder Jetting.

Our piFLOW® conveyors can be easily integrated to existing machine parks and production lines. We offer seamless integration of automated vacuum conveying solutions into any powder-based manufacturing process. The piFLOW® conveyors:

- avoid exposure to hazardous materials of technicians while not compromising on production efficiency

- enhance overall efficiency and productivity through automated powder handling

- reduce supply chain disruptions by offering a more streamlined manufacturing process

- ensure that the material doesn't degrade, and powder mixes don't segregate during the manufacturing process

- minimize the risk of contamination through a closed-loop system, with easily cleanable and sanitizable conveying equipment.

With Piab’s products, you can connect the dots within the Additive Manufacturing production line with ease!

Metal additive manufacturing and the automation of powder handling

Shortened development cycle

Metal additive manufacturing is a method used both for prototyping and increasingly for serial production of metal parts. It gives the possibility to design and produce previously impossible components or use custom alloys. Component delivery gets faster due to a shortened development cycle. Metal Additive manufacturing reduces supply chain disruptions and contributes to reduced part weight.

Powder handling automation

Given the high growth rates and increasing opportunities in the additive manufacturing industry, powder handling automation is key to establishing the technology as a standard production process. However, many process steps are still manual. This includes the loading of the production equipment with the appropriate metal powder. Furthermore, the use of vacuum conveying technologies can help protect people, products, and the environment.

Ideal vacuum conveyors

With our extensive experience in material handling, Piab's vacuum conveyors have long been an efficient solution for the AM process. Piab's premium conveyors are equipped with a stainless steel (ASTM 316L) housing and feature Piab's patented and highly efficient COAX® vacuum technology. They are ATEX dust and gas certified and have built-in automatic filter cleaning. Piab has conducted in-house tests on various metals and alloys, which have shown that our vacuum conveyors can handle powders with a bulk density of 8 kg/liter [500 lbs./ft3] and an impressive throughput.

A variety of additive manufacturing technologies

Working with a variety of Additive Manufacturing technologies, such as Powder Bed Fusion and Binder Jetting, Piab offers the greatest flexibility in integrating automated vacuum conveying solutions into any powder-based manufacturing process.

Piab and the metal additive manufacturing industry: Strong success stories

Enhancing Innovation: Piab & IB Joint Expertise

IB is a renowned leader in the manufacturing of highly customized machines and an accomplished supplier for powderhandling solutions. This collaboration enhances Piab's in-house expertise, product portfolio, and offerings in the additive manufacturing industry, focusing on advanced metal powder conveying solutions designed to meet the evolving needs of our clients.

Piab & IB’s solutions support KSB's growth

KSB, a premier provider of pumps, valves, and systems across diverse applications reduced their powder handling setup time, using the IB ultrasonic sieving station MPS30 with an integrated Piab piFLOW® vacuum conveyor. They increased productivity and efficiency and reduced the need for manual labor.

Previously we did manual powder handling and then sieving the powder and transferring it back to the [3D printing] machine, which was very timeconsuming: [...] took up half of a day. Right now we can just remove the powder from the machine, sieve it, and refill the machine in less than 30 minutes.

Solukon relies on vacuum conveyors from Piab in its new Powder Collection Unit

Solukon and Piab have established an exciting collaboration, where innovative vacuum conveyor technology is boosting the efficiency and safety of powder-based 3D printing. The Solukon Powder Collection Unit (SFM-PCU for short) is a fully automated powder collection solution for metal powders. With the help of the piFLOW®i vacuum conveyor from Piab, Solukon makes powder handling simpler and safer right after depowdering.

IB Sieving Stations

Ultrasonic screening for printers with large building chambers

The MPS 30 from IB Additive is an ultrasonic screening station with integrated pneumatic conveying for printers with large build chambers.

It is highly reliable, enabling used powder to be fed directly from the building chamber of the 3D printer via the integrated Piab vacuum conveying system.

In 2023, Piab Group acquired IB Verfahrens- und Anlagentechnik GmbH & Co. KG, a company specializing in customer-specific systems for bulk material handling.

Ultrasonic screening for small build chambers

IB Additive’s MPS5 is an ultrasonic screening station with integrated pneumatic conveying for printers with small build chambers. It is a pinter-independent, process-stable, powerful and compact solution for powder recovery.

Sieving station for metal powder handling via containers

The MPS X1 from IB Additive is an effective solution for powder recovery from IB Additive. It enables the feeding of already used powder and the return transport of the recycled powder via existing containers.

Download the MPS X1 manual here

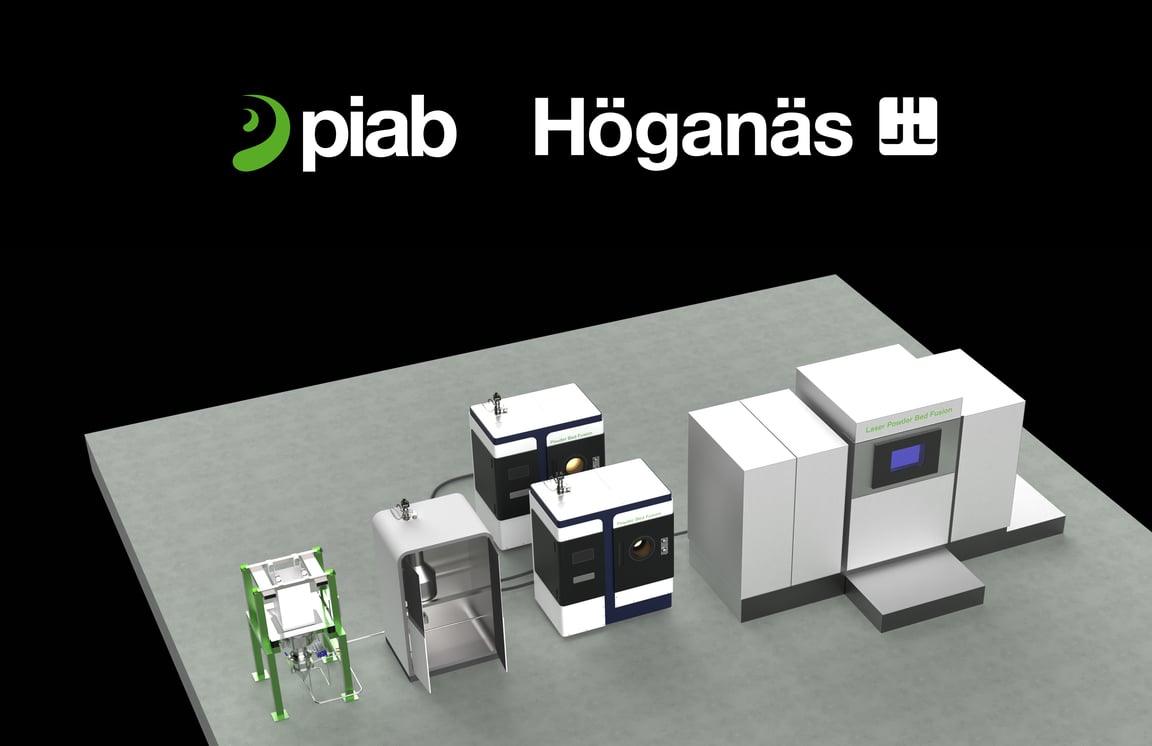

Piab & Höganäs: In partnership with a metal powder producer

Piab has set a partnership with Höganäs, a Swedish company producing a variety of metal powders.

Through this partnership, we offer big bag/flexbag unloading stations with integrated vacuum conveying for more sustainable ways to work with metal powders. We contribute to industrialization, reduce manual handling, and optimize the amount of powder used in industrial processes.

FAQ

What metal powders can be transported by Piab vacuum conveyors?

Piab vacuum conveyors are capable of transporting a wide range of metal powders. Piab has conducted conveying tests with various powders, including: Aluminum, SS316L, Inconel, Wolfram Carbide, Titanium, and others.

Apart from metal, can you convey other materials used in 3D printing technologies as well?

Yes, Piab vacuum conveyors can also handle plastic, as well as sand and ceramics used in different 3D printing technologies. Fill out the form below to get advice on your specific material at hand.

Do you provide inert conveying/sieving?

Inert conveying is often required for Titanium and sometimes for Aluminum, while other materials mentioned typically do not necessitate inert-gas conveying. Piab offers inert conveying solutions, and the sieving solutions are inherently equipped with inertization.

What conveying capacity for metal powder can be achieved by using Piab solutions?

The conveying capacities achieved with Piab solutions greatly depend on the specific segment of the AM production process. Piab has conducted extensive testing with various powders and distances. Our systems have demonstrated the ability to maintain conveying capability over distances of up to 50 meters [164 feet], with a capacity of up to 1.9 t/h at 20 meters [65 feet] for Aluminum and Stainless steel powders.

What equipment can be supplied by Piab?

Piab offers a comprehensive range of equipment for additive manufacturing applications. Our offerings include powder discharge stations, single or multiple conveying lines, and sieve stations. Piab excels in providing customized solutions and turn-key systems to effectively handle the entire powder handling process.

Get help choosing your ideal conveying equipment!

Find out what applies to your raw materials and products! Fill in the form to get free, personal advice from our engineers as well as comparisons with other technologies to find the best solution for your needs.