Automation by vacuum technology

Most industrial sectors and companies can increase productivity and efficiency with a focus on internal process and workflow improvements. Hence, process automation is a powerful tool. It allows a work environment where the staff can focus on strategy, innovation and technology, where harmful work tasks are reduced and where production costs are balanced. Our vision is an automated world where all resources count and no humans are injured.

Vacuum automation

Where is an automated process needed?

Manufactured products must transition through various stages of processing such as raw material handling, assembly, sorting and packaging. Piab has for decades successfully developed systems to support all these industrial process steps and functions. Our solutions are found in sectors such as food & beverage, automotive, packaging, e-commerce, electronics, chemicals, pharmaceuticals, battery production and many more.

All materials can be handled

Porous (leaking) materials allow air to pass through them, such as cardboard, fabric, or foam. When a vacuum system is used to handle these materials, air continuously leaks into the system due to the material's porous nature. This means the vacuum pump must have the capacity of a constant pressure to maintain the desired vacuum level and hold the objects. This requires a vacuum system with a high flow rate.

Non-Porous (Solid) materials such as metal, glass, or plastic - do not allow air to pass through them. When handling non-porous materials, the vacuum system is able to create a seal, and once the desired vacuum level is reached, no additional air flow is needed unless the seal is broken. The capacity of the vacuum pump for such systems is determined by how fast the system can be evacuated to a certain vacuum level.

Centralized or decentralized vacuum system

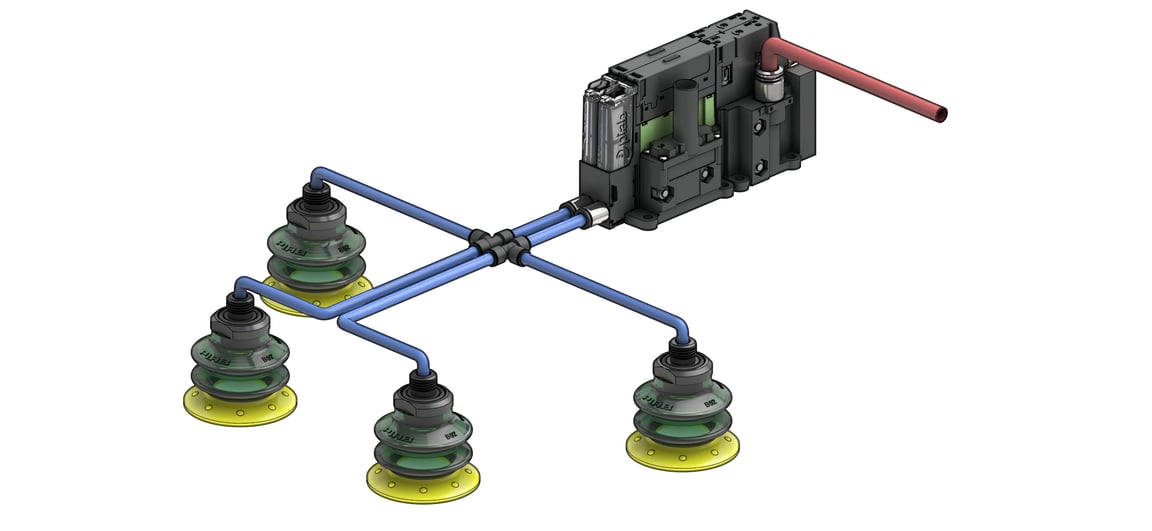

A centralized vacuum system uses a single vacuum pump that serves multiple suction points. The pump is usually in a fixed location and connected to the suction cups through a network of tubes. The advantage of a centralized system is that a single vacuum pump is easier and more cost-effective to install, maintain, and operate than multiple pumps. The latter is however more flexible when certain safety measures are considered.

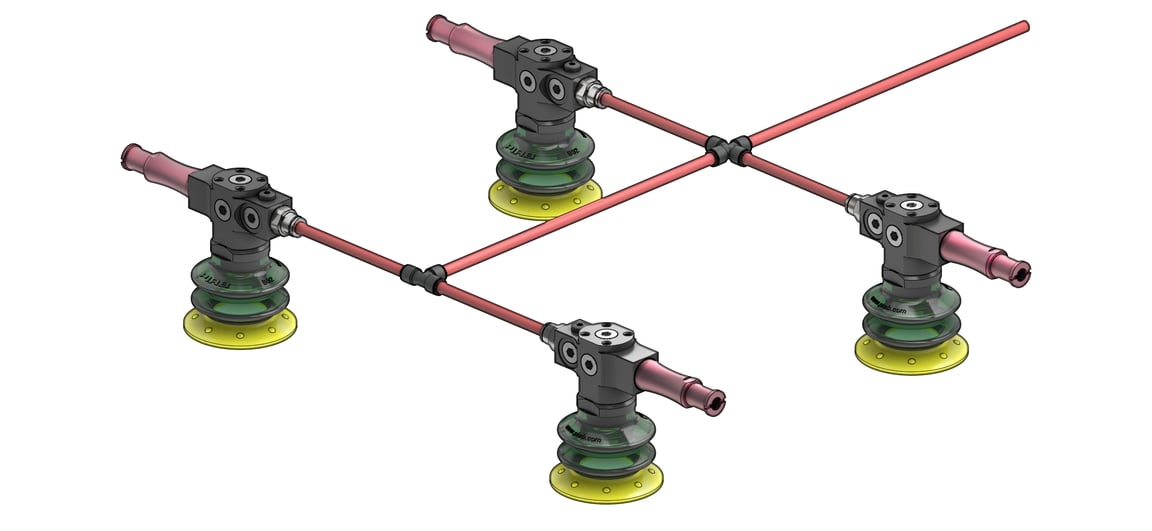

In a decentralized vacuum system, every suction point has its own dedicated vacuum pump. This means that each suction cup operates independently, which enables increased efficiency and reliability. If one suction cup cannot reach the target object, it does not affect the operation of the others. In addition, decentralized systems may offer greater flexibility, as they can be easily adjusted or expanded in numbers to meet changing operational needs.

Our COAX® technology

A COAX® cartridge contains an advanced solution for vacuum creation. The name was derived from the coaxial fitting of components around the nozzles. A system based on COAX® technology is extremely reliable and can provide three times more vacuum flow than conventional vacuum systems allowing increased cycle speed and reduced energy consumption. Piab invented COAX®, hence our vacuum pumps are predominately based on this technology.

Ask us anything.

Receive free consultation and advice from our automation specialists on how to reinforce your process.

Why automation by vacuum technology?

Improved productivity

Vacuum automation may significantly reduce manual labour, thus increase productivity. It also ensures consistent performance and quality.

Safe work environment

A vacuum-driven system contributes to a better work environment by reducing harmful work tasks. Such improved ergonomics enable increased safety for staff and handled products.

Flexibility

Vacuum automation systems are highly flexible and can be configured according to specific needs in many applications. This includes all our vacuum pumps, suction cups, and grippers.

Independence

Our range of vacuum-driven products can be used with either industrial robots and cobots or as parts in ergo tools, gantries, and other machinery within many industrial sectors and production processes.

Product safety

Our vacuum-driven tools can safely handle objects ranging from very small, delicate, and fragile items to large and heavy sheet materials completely mark-free, even in harsh or hazardous environments.

Energy saving

Vacuum systems powered by Piab's COAX® ejectors consume minimal energy and reduce operational costs, thus the environmental impact.

Tolerance to tight spaces

Piab components are well-engineered and compact, requiring minimal floor space. This makes them an ideal choice for environments with a very tight footprint.

High reliability

Due to their design and technology, vacuum systems are highly reliable with a long service life. They have few moving parts, which reduces the risk of breakdown and the need for maintenance.

How do I choose the right system?

Before selecting a vacuum-driven system, it's crucial to have a clear understanding of your operational needs and objectives. Here are some key factors to consider and plan:

- Understand your application. Identify the specific requirements of your application. This includes the type of materials you'll be handling, their weight, size, shape, and porosity. Also, consider the speed and precision required.

- Determine system type. Decide whether you need a centralized or decentralized vacuum system. A centralized system uses one vacuum source for multiple suction cups, while a decentralized system has each suction cup with its own vacuum source.

- Choose the right vacuum pump. The choice of vacuum pump is crucial. You need to consider the pump's capacity, its ability to achieve the required vacuum level, and its evacuation time.

- Select appropriate suction cups or foam grippers. The suction cups should be suitable for the material you're handling. Consider factors such as the size, shape, and material of the suction cups.

- Safety requirements. Understand the safety requirements of your operation. This includes assessing the reliability of the system and determining any necessary safety features.

- Energy efficiency. Consider the energy efficiency of the system. Vacuum systems with energy-saving features can significantly reduce operating costs.

- Evaluate maintenance needs. Understand the maintenance requirements of the system. Some systems may require more frequent maintenance or have more expensive parts to replace.

- Cost considerations. Consider the total cost of ownership, including the initial purchase price, operating costs, and maintenance costs.

- Environmental impact. If sustainability is a concern for your operation, consider the environmental impact of the system, including its energy use and CO2 emissions.

Remember, the best vacuum system for your process will depend on your specific application and operational requirements. Planning and careful consideration of these factors will help ensure that you choose a system that delivers optimal performance and value.

Do not hesitate to contact our engineers for useful advice.

Products & solutions

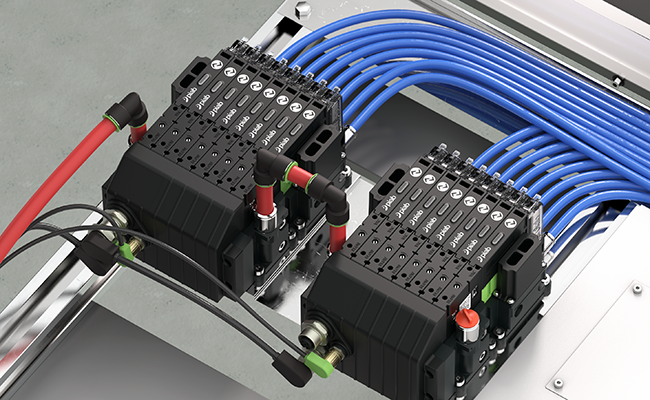

Vacuum pumps and ejectors

A vacuum ejector from Piab is the driver of a successful vacuum system and may be used in both centralized and decentralized vacuum systems, i.e. one ejector to serve all suction cups, or one ejector per suction cup. Regardless of system preference, our ejector range can be adapted to any application and allows for safe and reliable product handling, many years to come.

Suction cups and soft grippers

Our suction cups and soft grippers offer superior handling of just any object: Round Suction Cups - for accuracy regardless of size, shape or material; Oval/Rectangular – for long, irregular objects; Modular – interchangeable concept with individually optimized parts for gripping, lifting and height compensation; Soft Grippers – gentle fingers to lift delicate objects like fruit; Foam Grippers – for precise picking of rough or unevenly placed objects.

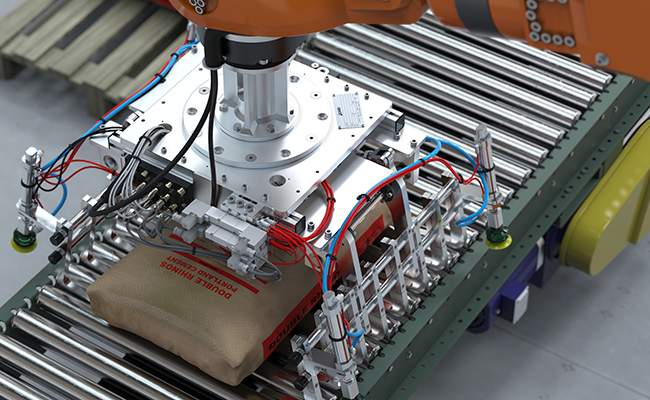

Robot and cobot gripping solutions

Piab's extensive portfolio of gripping solutions for industrial or collaborative robots contains products with unparalleled qualities - like piCOBOT® a multipurpose vacuum ejector program for cobots, or Kenos® - leading brand for large area gripping systems. Tailored palletizing tools are included in this segment, as are custom-made industrial applications with the highest level of specialization.

Robot End Of Arm Tooling components

Robot End Of Arm Tooling - EOAT – is a core area within Piab Group. We offer a vast range of components for applications such as palletizing, ergonomic handling equipment and parts/sub-systems for industrial and collaborative robots. Our advanced gripping solutions are most often designed to be installed directly on the arm or tool changer of most robot/cobot brands.

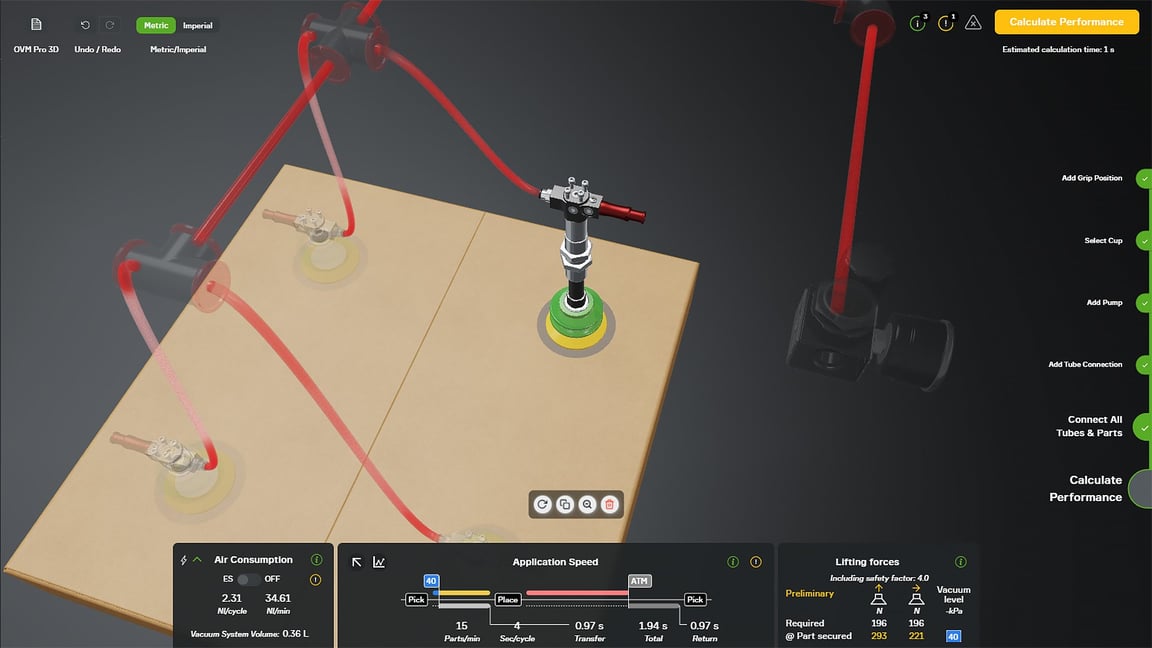

Design your own vacuum system

OVM Pro 3D offers you to design, test, and refine your own vacuum system in a virtual environment before physical implementation. Log in and create a unique application with Piab’s extensive range of vacuum ejector pumps, suction cups, grippers, fittings and accessories.

Further reading

Need guidance? We are here to help.

Fill out the form for more information about vacuum technology and how this can enforce your process, or if you need general advice from our automation specialists.