- Nyheter

- Visors protecting people against COVID-19 from Somtech are now handled with Piab components

Visors protecting people against COVID-19 from Somtech are now handled with Piab components

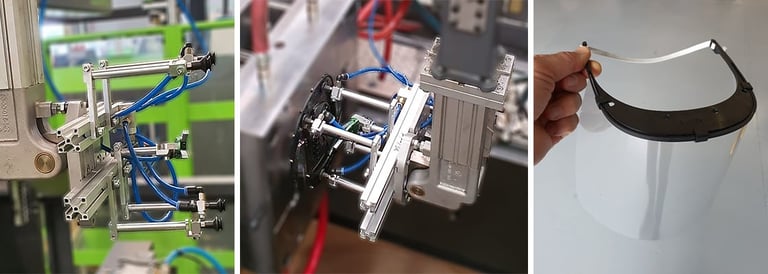

To help protect people from the COVID-19 virus while they keep up a minimum of essential daily tasks, Somtech Technologies SL in Valencia, Spain have changed production of their visors from 3D printing to injection moulding. To be able to start production immediately after setting up the injection molding equipment, Somtech needed components overnight to build the robot hand that automatically unload the machine. The only company able to match their urgent request with the right parts was Piab. The fast delivery allows Somtech to produce 56,000 visors a week with immediate effect.

With the continuing speed of spreading COVID-19 infections, technology companies are in a race to come up with innovative solutions that can be produced at least at an evenly quick rate. One of the companies in COVID-19 battled Spain – Somtech Technologies – have therefore changed their product focus from automotive, rail and packaging industries to producing visors. To keep up with requirements, production technology was shifted from 3D-printing to injection moulding to meet the ever increasing demand of the newly developed visors. Normally used in motorcycle helmets, visors now shield health care personal in clinics and other essential professionals from the virus to keep them healthy during their important task. Additionally, it can be used when going to supermarkets, pharmacies or banks to stock up on food, medication and household consumables.

This change to an injection molding process was only possible by installing an automated removal system with a suitable gripper to be attached to the robot.

Mariano Sebastiá Ramirez, Chief Operating Officer (COO) of Somtech Technologies comments: “When we approached all possible manufacturers of gripping components over the weekend to obtain components at the beginning of the following week, the Piab experts immediately sprang into action, even on a Sunday night. This allowed us to define the necessary parts and have the order ready by Monday morning. Within 48 hours, the Piab components reached our factory allowing us to immediately ramp up the process and start high volume production of the visors.”

Sergio Luzuriaga, responsible Area Sales Manager at Piab in Spain adds: “We truly appreciate the trust from Somtech Technologies and are prepared to support them in all their requirements to help us fight COVID-19 and thereafter in hopefully coming soon normal times.”

The special modular system from Piab allows the simple combination of different parts ranging from low-maintenance and durable high-end gripper systems for precise transfers and processes as well as customized robot hands and pneumatic cutting tongs to complete cutting systems. In addition, Piab components are equipped with vacuum-based automation solutions for gripping and moving a wide variety of products and serve customers in the automotive, medtech, food, pharma and packaging industries as well as in metalworking and plastic injection molding.

About Piab

Piab provides smart solutions for the automated world, helping thousands of end users and machine producers in e-commerce logistics, food, pharma, automotive and other manufacturing industries to improve energy-efficiency, productivity and working environments. With more than 500 employees and SEK 1,2 bn in sales 2018, Piab is a global organization, serving customers in almost 70 countries from a network of subsidiaries and distributors. By leveraging the ongoing technological development in automation and robotics, and targeting high-growth segments and geographies, Piab's vision is to become the global leader in gripping and moving solutions.

More information

Kajsa Blixth, Vice President Marketing and Communications Manager

Tel: +46 (0) 8 630 25 85

E-mail: kajsa.blixth@piab.com