All News

Safe automatic handling of glass sheets with Piab’s vacuum technology

Forvet SpA has created end-of-arm tools that allow handling glass sheets of different sizes...

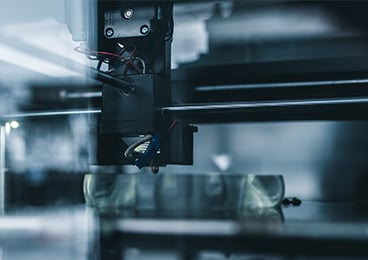

Piab introduces piFLOW®am

The piFLOW®am is a small vacuum conveyor designed based on requirements from OEMs within the Additive...

Ergonomic hazards in the Food industry and how to eliminate them

The food production line is a hazardous one. Therefore, it is extremely important to avoid...

Now available – the gripper for automated handling of six-packs

With Piab’s new gripper, six-packs with cardboard wrapping can be handled automatically, gently and...

Respiratory hazards in the Food industry and how to eliminate them

With allergies, asthma, and other conditions becoming more frequent, processors need to implement changes...

With Piab’s area gripper, the handling of furniture parts is child's play

The machine builder GO GmbH were looking for an “all-in-one” gripper solution that can be used to stack both loose and packaged furniture parts on and off pallets, as well as the pallets themselves. The solution was...

Delivering clean sugar with Piab’s piFLOW®p vacuum conveyor

To improve product quality and prevent losses India’s leading manufacturer M. B. Sugar trusts...

At Nipro the piCOMPACT® provides the vacuum performance needed in production of pharma packaging made of glass

With 32,500 cycles per day, 24 hours a day, seven days a week, this application is one of those with the highest number of...

JAM Automation moves 250kg heavy profiles with Piab’s Kenos® grippers

To automaticaly remove extruded aluminium profiles from cassettes in high-bay warehouses, JAM Automation created...

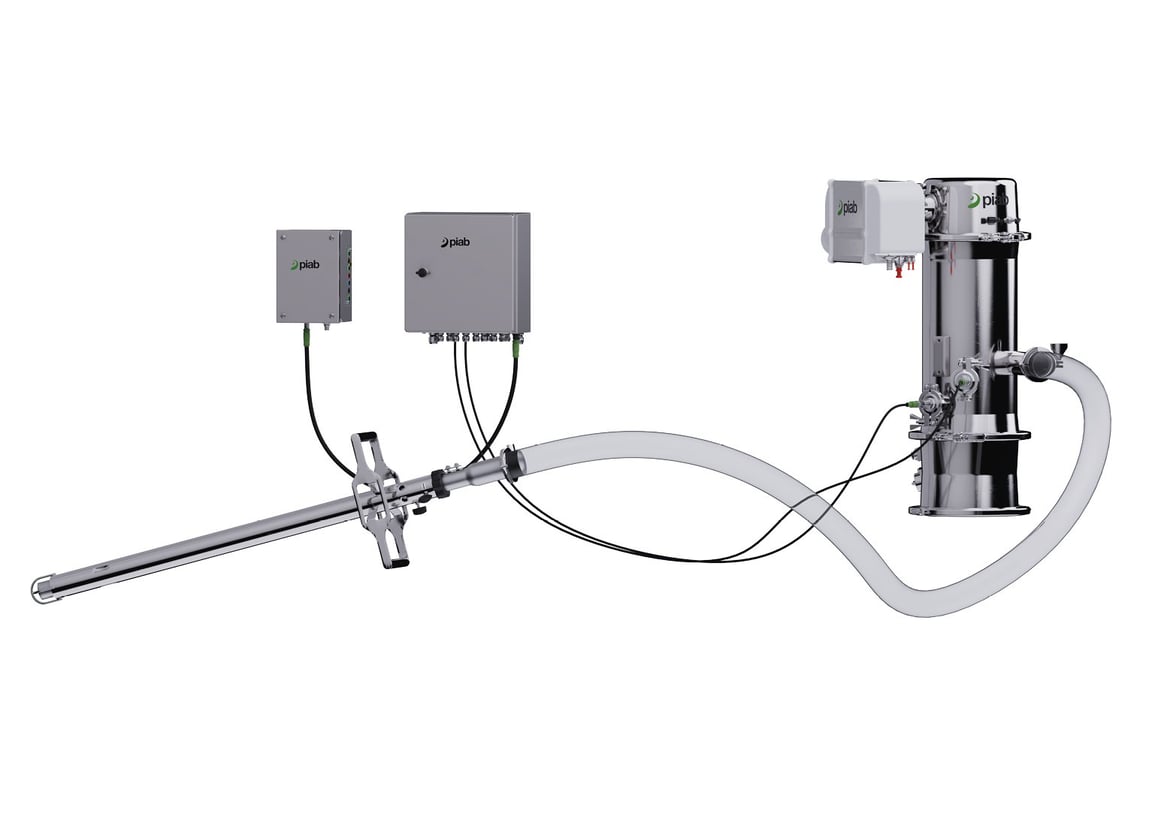

Automating powder handling in Additive Manufacturing

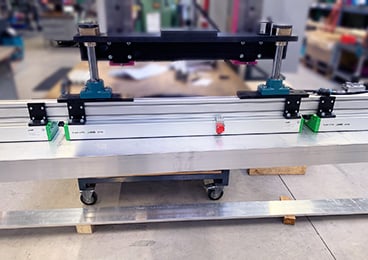

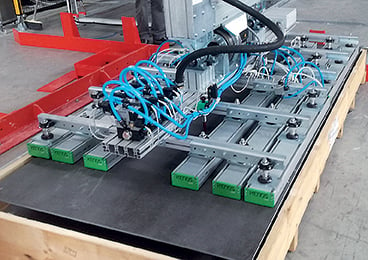

Automating metal powder handling is key to establish the Additive Manufacturing technology as a standard process. Piab’s vacuum conveying powder...

Automatic handling of porcelain stoneware slabs and related sub-formats

Thanks to Piab's Kenos® KVG area vacuum gripper, an extreme variability of sizes and surfaces can be managed, using just a single gripper. This allowed...

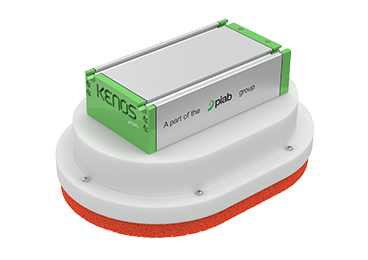

Piab extends the Kenos® Sack Gripper program

The highly reliable Kenos® KSG gripper is now extended with a new smaller size, sealing ring and can now also be configured with...

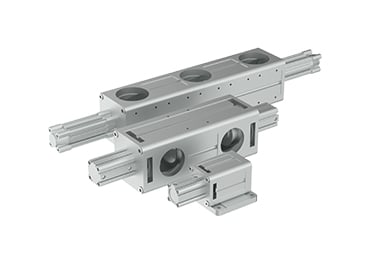

Kenos® Reverse valves program is extended

The KRV reverse valve controls the air flow and is typically used in external vacuum generator systems. Robust and reliable, KRV valves are offered in models for...

High flexibility and safe gripping in a cosmetic application with Piab's cobot gripper

Effedi Automation chose the piCOBOT® gripper, COAX® vacuum technology and BX suction cups by Piab to handle the palletizing operations of a...

Getting a grip on battery cell handling with Piab’s vacuum technology

From electrode stacking between Z-fold separators, pouch cell and gap filter to heatshield handling in...

Piab extends the VGS™ product range with VGS™4005

The VGS™4005 is geared to cater for mid-range applications where less vacuum depth is needed. The vacuum gripper ejectors are robust, easy to use and designed to...

Industrial Bakery Austerschmidt in Germany automates handling of seeds with Piab’s vacuum conveyors

Employee relief and careful use of resources prompted the industrial bakery Austerschmidt in Germany to switch the handling of seeds from a manual to an automated process. In piFLOW®f vacuum conveyors, they found the critical tools.

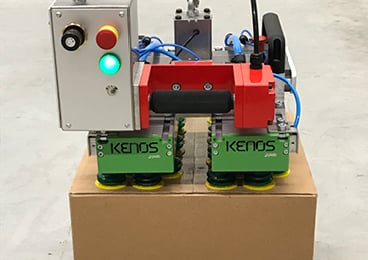

With Piab's gripper, Best Handling Technology improves the ergonomics of its customer at 32 workstations

Healthy, satisfied employees, increased efficiency, flexibility, and sustainability - regardless of the industry, the reasons are always the same that give cause to a higher degree of automation in handling tasks. German Best Handling Technology was able to achieve all of this for its customer, a leading logistics service provider, with a suction cup equipped Kenos® area gripper.

DCL realizes flexible automation solution with Piab’s piCOBOT® vacuum gripper on an UR 10e robot

Looking for a flexible, easy to integrate, plug-and-play solution to handle picking and packing of items into boxes in their fulfilment center DCL Logistics based in Fremont, CA, resorted to an UR 10e robot combined with Piab’s piCOBOT® vacuum gripper.

Conveying made easy with Piab’s piFLOW®p SMART Conveying Cycle Optimizer (CCO)

Wouldn’t conveying more material at the same time, with less requirements on operator skills and saving on energy costs sound great? If so, check out Piab’s newest edition to its premium conveyor series.

Piab launches the Vacuplus ejector series for low to mid-range applications

As a part of our ambition to expand our global portfolio, we at Piab are thrilled to present the launch of our Vacuplus ejectors, geared to cater for low to mid-range applications that cannot compromise on ejector performance.