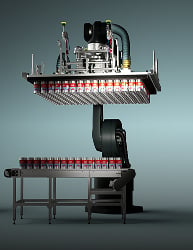

New Product: piCLASSIC™ Neo

Compact and configurable vacuum pump powered by Piab’s multistage COAX® technology — delivering reliable performance, easy maintenance, and energy-efficient operation for sustainable manufacturing.

Smarter automation for every industry

Piab delivers efficient vacuum automation solutions that boost productivity and sustainability across global industries.

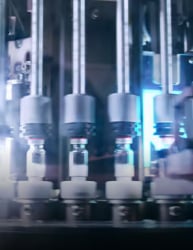

Innovative products for automation

Our vacuum technology enables precise handling, efficient conveying, and smart integration across automation systems.

Find the right products for your application.

Piab focuses on pioneering technology, innovation and the products of tomorrow, helping you to solve the present and the future. Get in touch with us to explore how we can support your next automation step.

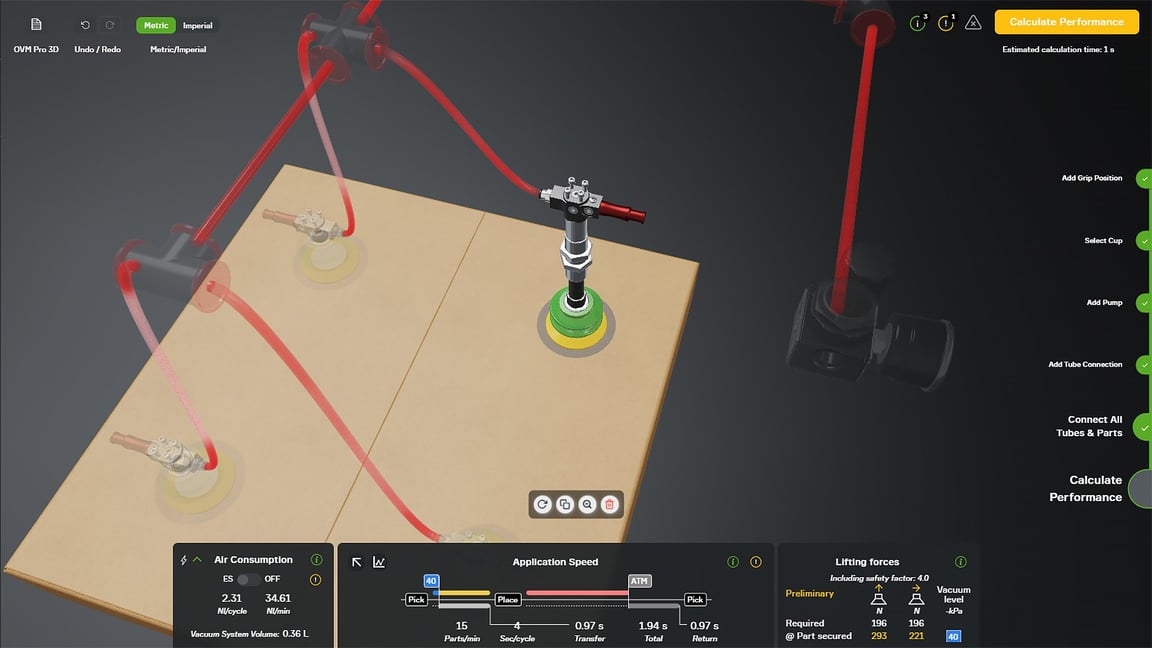

Design your own vacuum system

OVM Pro 3D offers you to design, test, and refine your own vacuum system in a virtual environment before physical implementation. Log in and create a unique application with Piab’s extensive range of vacuum ejector pumps, suction cups, grippers, fittings and accessories.

Upcoming events

Latest news

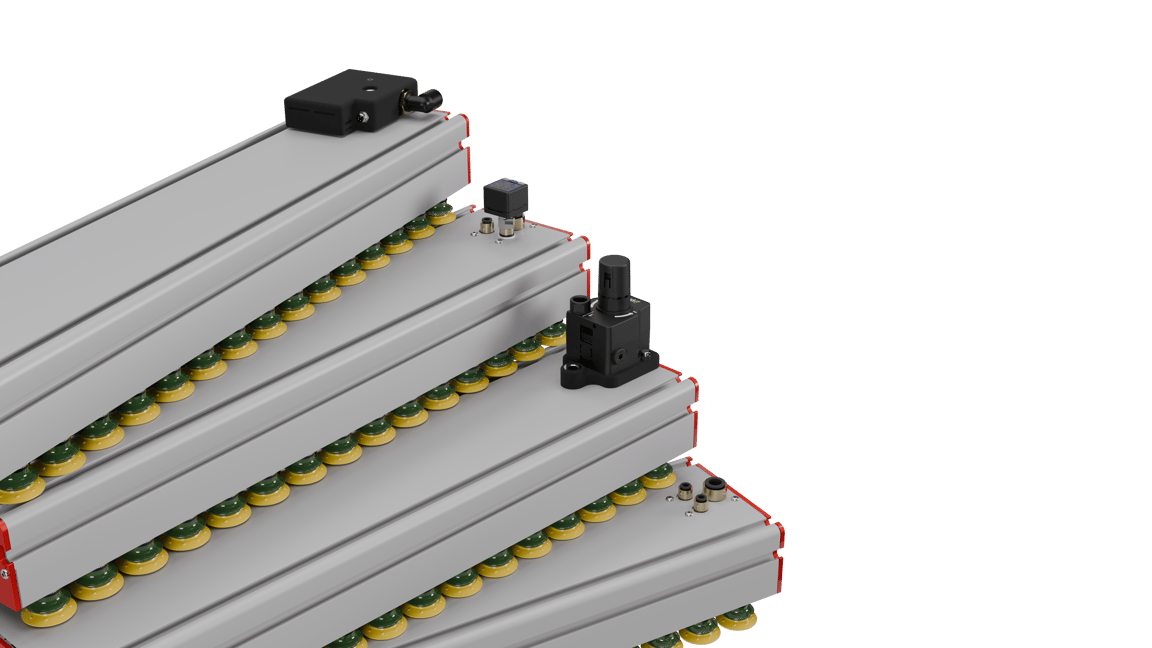

Kenos® expands vacuum grippers KVG150 E-series

Piab Group’s European Supply Unit Relocates to Modern Facility in Butzbach

Introducing New Sizes to the BGX Family: 27mm and 63mm for Enhanced Bag Handling

Sign up

Create your free Piab account

Sign up for free to access detailed product information, CAD models, and documentation that simplify your design and selection process.